What is a bottle capping machine?

The Bottle Capping Machine is used to cap bottles automatically. This is designed for use in an automated packing line. This machine is a continuous capping machine, not an intermittent capping machine. This machine is more productive than intermittent capping because it presses the lids more tightly and causes less damage. It's now widely used in the food, pharmaceutical, and chemical industries.

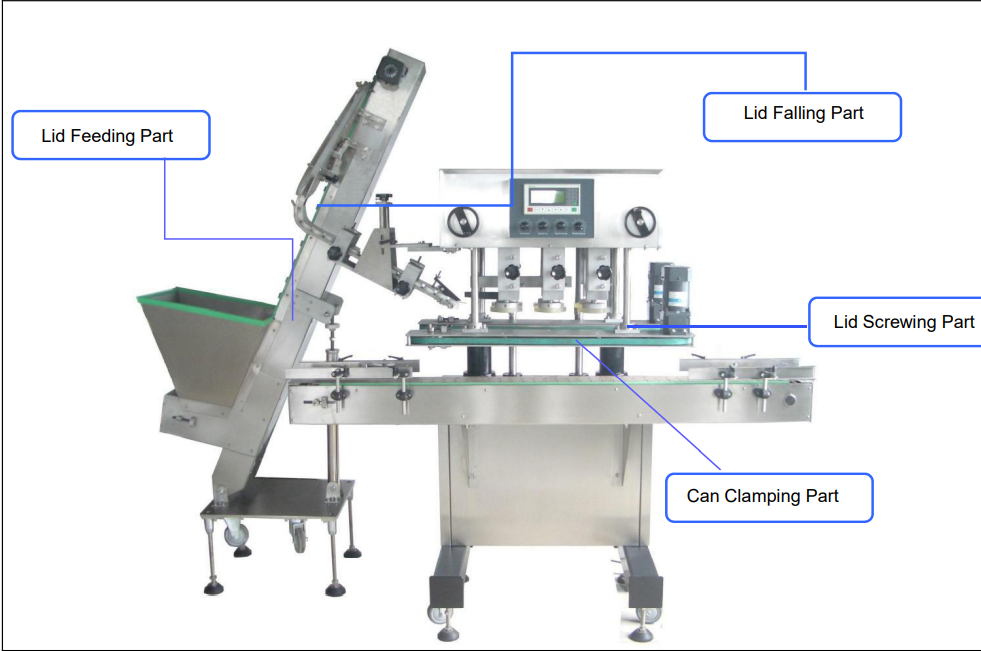

Structure:

What are the main characteristics?

• For different shaped and material bottles and caps.

• Easy to operate using PLC and touch screen control.

• High and customizable speed, suitable for all types of packing lines.

• The one-button start feature is quite efficient.

• The comprehensive design makes the machine more humanized and intelligent.

• A good ratio in terms of machine appearance, as well as a high-level design and appearance.

• The machine's body is made of SUS 304 and complies with GMP guidelines.

• All pieces in touch with the bottle and lids are made of food-safe materials.

• A digital display screen will show the size of different bottles, making changing bottles easy (Option).

• Optronic sensor to recognize and remove improperly capped bottles (Option).

• Use a stepped lifting device to automatically feed in lids.

• The lid-pressing belt is inclined, allowing the lid to be adjusted into the right position before pressing.

What is the application?

The bottle capping machines can all be operated with bottles with screw caps of different sizes, shapes, and materials.

1.Bottle size

It is suitable for bottles of 20–120 mm in diameter and 60–180 mm in height. Outside of this range, it can be changed to fit any bottle size.

2.Bottle shape

The bottle capping machine can cap bottles of all shapes and sizes, including round, square, and sophisticated designs.

3.Bottle and cap material

Any type of glass, plastic, or metal can be used in the bottle capping machine.

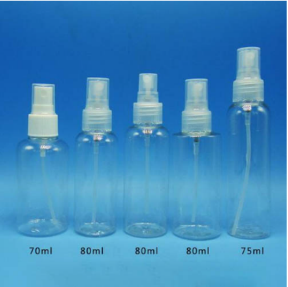

4.Screw cap type

Any style of a screw cap, such as a pump, spray, or drop cap, can be screwed on using the bottle capping machine.

5.Industry

Powder, liquid, and granule packing lines, as well as food, pharmaceutical, chemical, and other industries, can all benefit from the bottle capping machine.

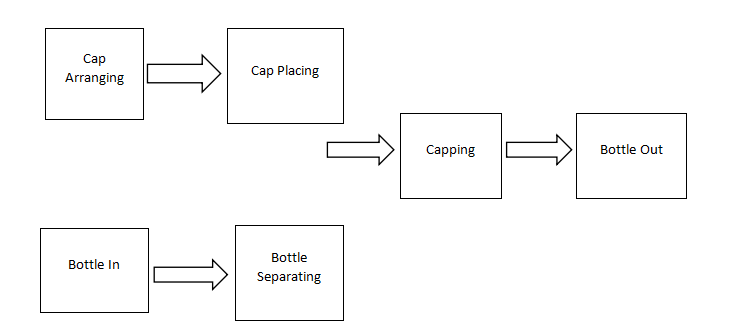

Working Process

Packing line

The bottle capping machine can be integrated with filling and labeling equipment to create a packing line.

Bottle unscrambler + auger filler + bottle capping machine + foil sealing machine.

Bottle unscrambler + auger filler + bottle capping machine +foil sealing machine + labeling machine

Post time: May-23-2022