When it comes to industrial mixing, both paddle mixers and ribbon blenders are widely used for various applications. These two types of mixers serve similar functions but are designed differently to cater to specific material characteristics and mixing requirements.

Both paddle mixers and ribbon blenders have their advantages depending on the specific needs of the application. Ribbon blenders are better suited for conventional powder mixing or large-volume blending, while paddle mixers are ideal for fragile materials, heavy or sticky substances, or formulations with a large number of ingredients and significant density variations. By understanding the material characteristics, required capacity, and mixing requirements, businesses can choose the most suitable mixer for their operations, optimizing both performance and cost-effectiveness. Below is a detailed comparison of the two machines across various aspects:

| Factor | Single Shaft Paddle Mixer | Ribbon Blender |

| Batch Size Flexibility | Efficient blending is possible with fill levels between 25-100%. | Effective blending requires a fill level of 60-100%. |

| Mix Time | It takes approximately 1-2 minutes to mix dry materials. | Dry applications typically require 5-6 minutes for mixing. |

| Product Characteristics | The paddle mixer mixes materials with different particle sizes, shapes, and densities evenly, preventing segregation. | It requires longer mixing times to blend ingredients of varying sizes, shapes, and densities, which could lead to segregation. |

| High Angle of Repose | The paddle mixer is suitable for materials with a high angle of repose. | Extended mixing times are necessary, and segregation can occur. |

| Shear/Heat (Friability) | The paddle mixer provides minimal shear and reduces the risk of product damage. | Moderate shear is applied, which may require extra time to achieve uniformity. |

| Liquid Addition | The mixing action brings materials to the surface quickly, enabling efficient liquid application to powders. | More time is needed to add liquid to powders without creating clumps. |

| Mix Quality | Mixes with a low standard deviation (≤0.5%) and coefficient of variation (≤5%) with a 0.25 lb sample. | Commonly, mixes have a 5% standard deviation and 10% coefficient of variation with a 0.5 lb sample. |

| Filling/Loading | Materials can be loaded randomly. | It’s recommended to load ingredients closer to the center for efficiency. |

1. Design and Mixing Mechanism

The paddle mixer is equipped with paddle-shaped blades attached to a central shaft. These blades rotate to create a mixing action that gently moves the material within the mixing chamber. Paddle mixers are generally more suited for materials that require gentle mixing, as they produce a less intense shear force.

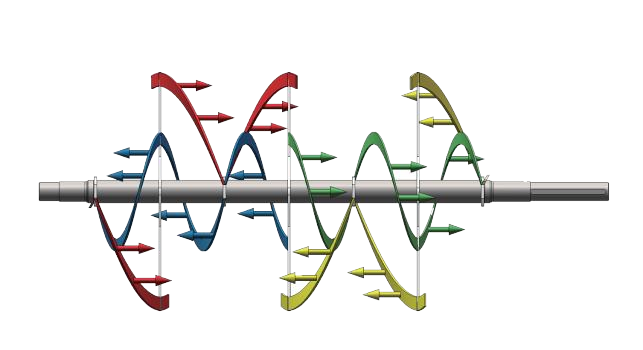

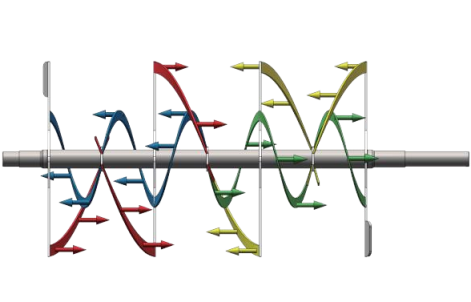

On the other hand, the ribbon blender consists of two ribbons—one inner and one outer—that rotate in opposite directions. The inner ribbon pushes the material from the center to the outer edges of the blender, while the outer ribbon pushes the material back toward the center. This design promotes more thorough mixing of materials, especially powders, and is often used for more homogenous blending.

2. Mixing Efficiency and Speed

While both mixers are designed to achieve uniform mixing, ribbon blenders are typically more efficient for handling dry powders and materials that need thorough blending. The counter-rotating ribbons in a ribbon blender help to quickly achieve a homogeneous mixture by efficiently distributing the materials. Ribbon blenders generally mix at a faster rate and are suitable for both small and large batch sizes.

In contrast, paddle mixers are slower in terms of mixing speed, but they can handle larger and denser materials better. Paddle mixers are more suitable for heavy or cohesive materials that require slower, more consistent mixing to avoid breaking down the material.

3. Material Compatibility

Both machines can handle a range of materials, but each has its specific advantages. Paddle mixers are particularly suitable for fragile, heavy, sticky, or cohesive materials, such as wet granules, slurries, and pastes. They are also ideal for mixing formulations with many ingredients or significant density variations. The gentle mixing action of the paddles minimizes damage to the material's structure. However, paddle mixers tend to generate more dust during operation, which can be a concern for certain applications.

Ribbon blenders, on the other hand, excel at mixing fine powders or combinations of powders and liquids. They are commonly used in industries like food processing, pharmaceuticals, and chemicals, where thorough and homogeneous blending is critical. The ribbon design ensures efficient mixing, especially for materials with similar densities, providing a more uniform blend in less time. Ribbon blenders are also better suited for large-volume mixing and conventional powder applications.

| Application Examples | Single Shaft Paddle Mixer | Ribbon Blender |

| Biscuit Mix | Suggested. Solid fat or lard should stay in chunks. Minimal shear is applied. | |

| Breading Mix | Suggested. Breadcrumbs, flour, salt, and other minor ingredients have varying particle sizes, shapes, and densities, with a high angle of repose. Minimal shear is applied. | |

| Coffee Beans (Green or Roasted) | Suggested. Maintains the integrity of the bean with minimal shear and reduced attrition. | |

| Flavored Drink Mix | Suggested. Shear helps disperse the powders, resulting in a highly homogeneous blend of sugar, flavor, and colorant. Shear is required. | |

| Pancake Mix | Suggested. Recommended with choppers if the blender is used for mixing a variety of products. | Suggested. Ensures very even dispersion of the fat and a smooth blend. Shear is required. |

| Protein Drink Mix | Suggested. Many ingredients with varying particle sizes and densities. Minimal shear is applied. | |

| Seasoning/Spice Blend | Suggested. High variation in particle size, shape, and density, with friable products like parsley and coarse salt. Minimal shear and heat are applied. | Suggested. Recommended only if a thick liquid is applied to the product (e.g., oil resin on salt). Shear is important to disperse the thick liquid. |

| Sugar, Flavor, and Colorant Mix | Suggested. Must keep nuts, dried fruit, and chocolate pieces intact. Minimal shear and breakage. Smaller batches are better. |

4. Size and Capacity

When considering capacity, ribbon blenders can typically handle larger volumes than paddle mixers. Ribbon blenders are designed to process high volumes efficiently, making them ideal for applications requiring bulk production. They can accommodate larger capacities and typically have higher throughput rates than paddle mixers.

Paddle mixers, however, are more compact and suitable for smaller batches or when a more flexible, versatile approach is needed. Due to their design, paddle mixers can provide a more uniform blend in smaller batches compared to ribbon blenders.

5. Energy Consumption

Ribbon blenders tend to consume more energy during operation due to the complexity of the design and the rapid mixing action. The counter-rotating ribbons generate significant torque and shear forces, which can require more power to maintain the desired mixing speed, especially with larger batches.

On the other hand, paddle mixers generally consume less energy due to the simpler design and slower mixing speed. The lower energy requirement can make paddle mixers a more energy-efficient option for applications where high-speed mixing is not necessary.

6. Maintenance and Durability

Both mixers require regular maintenance, but the design of the ribbon blender often makes it more challenging to maintain. The ribbons can wear out over time, especially when handling abrasive materials, and they may require frequent inspection and replacement. However, ribbon blenders are generally durable and robust, making them suitable for continuous use in demanding environments.

Paddle mixers are easier to maintain because their simpler design reduces the likelihood of wear and tear. They have fewer moving parts and require less frequent maintenance. However, paddle mixers may be less durable when handling particularly abrasive or harsh materials.

7. Cost

The cost of a ribbon blender is generally similar to that of a paddle mixer. While the ribbon blender’s mixing structure is more complex, with its counter-rotating ribbons, the pricing from most manufacturers tends to be comparable. Both types of mixers are competitively priced, making the choice of one over the other less influenced by cost but more by the specific application needs.

Paddle mixers, being simpler in design, may offer some cost savings in certain situations, but in terms of pricing, the difference is typically negligible compared to ribbon blenders. For smaller operations or less demanding mixing tasks, both types of mixers offer economical options.

8.Double Shaft Paddle Mixer

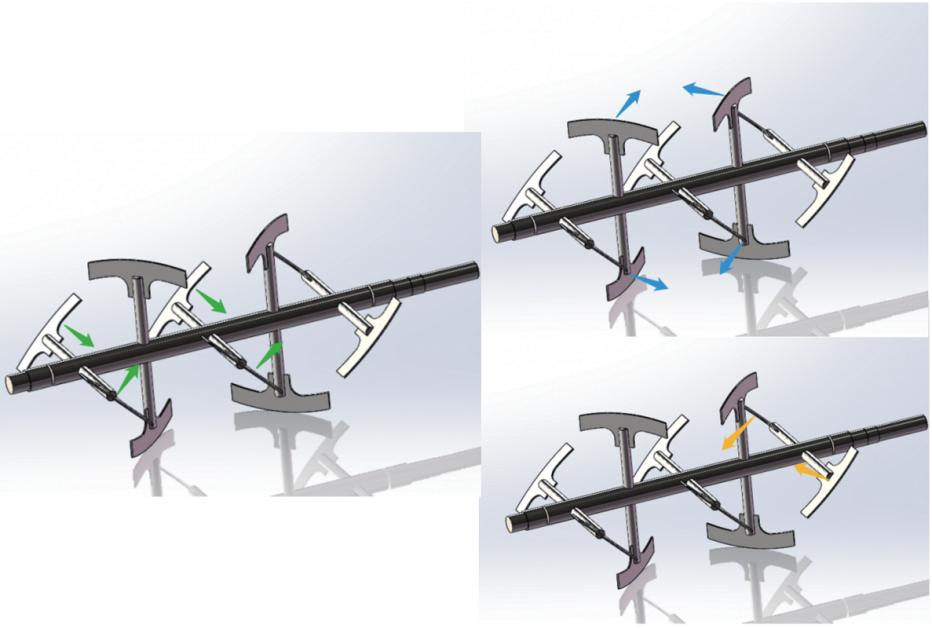

The double shaft paddle mixer features two rotating shafts that can be controlled in four modes: same direction rotation, opposite direction rotation, counter-rotation, and relative rotation. This versatility allows for efficient and tailored mixing of materials.

The double shaft paddle mixer is known for its superior efficiency, offering up to twice the mixing speed compared to both ribbon blenders and single shaft paddle mixers. It excels at handling sticky, coarse, or wet materials and is widely used in industries like chemicals, pharmaceuticals, and food processing.

However, the enhanced mixing performance comes at a higher cost, typically significantly more expensive than both ribbon blenders and single shaft paddle mixers. The price premium is justified by its high efficiency and ability to handle a wider range of materials and more complex mixing tasks, making it suitable for medium- to large-scale operations.

If you have any further questions regarding the principle of the ribbon blender, feel free to contact us for consultation. Leave your contact information, and we will get in touch with you within 24 hours to assist and clarify any doubts you may have.

Post time: Mar-06-2025