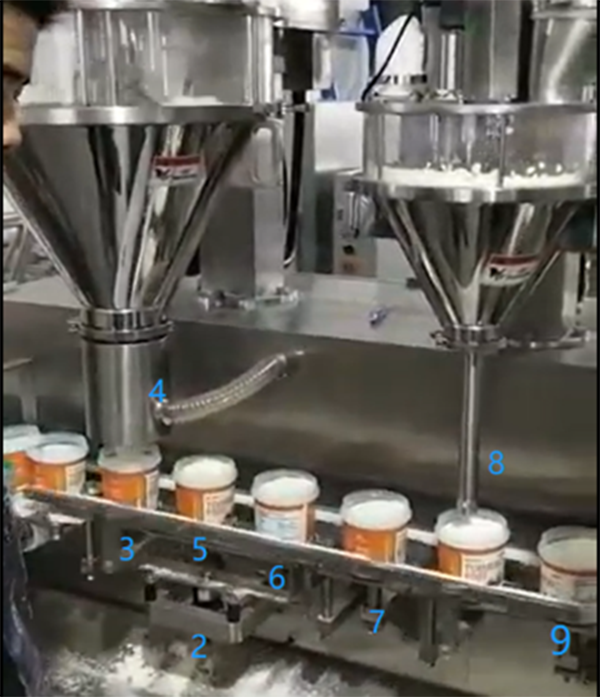

A dual-head auger filler is a type of a filling machine that is often used in the packaging sector for dispensing purposes and filling powdered or granular materials into containers such as bottles, or even jars. Its functioning is comprised of several main components:

Auger Filling System:

The dual-head auger filler transports and dispenses the product using two augers or screw mechanisms. A motor drives each auger, which revolves within a cylindrical tube, pushing the product ahead of it.

The dual-head auger filler transports and dispenses the product using two augers or screw mechanisms. A motor drives each auger, which revolves within a cylindrical tube, pushing the product ahead of it.

Hopper and Product Feeding:

This machine has two hoppers. One for each product has to be filled. The hoppers ensures that the product is delivered consistently and continuously to the augers, allowing for continuous filling.

Product Dispensing and Metering:

The augers draw the product from the hoppers and convey it to the filling area as they rotate. The pitch of the augers determines the volume of product distributed per rotation. This system allows on exact product metering, resulting to an accurate filling.

Fill Control:

The twin-head auger filler provides filling control. The augers’ speed and rotation can be measured to control the filling rate and reach the required weight or volume of goods in each container. This control ensures that the filling outcomes are consistent and repeatable.

Dual Filling Heads:

“The auger filler’s dual-head arrangement” increases efficiency and productivity. The two containers can be filled at the same time, lowering overall filling time, and improving production. It is very useful for stocking huge quantities of things.

Filling Accuracy and Consistency:

The auger filler enables a precise container filling. The combination of precision metering, filling process control, and dual filling heads reduces fluctuations in fill weights or volumes, resulting in consistent and uniform packing.

Quick Changeover:

The two-head auger filler is designed for a quick and easy product or container size changes. The hoppers and augers may be simply removed and replaced, and the machine settings can be altered to meet a variety of filling needs.

Integration with Packaging Lines:

The twin-head auger filler may be smoothly incorporated into packaging lines, functioning in tandem with other equipment like conveyor belts, capping machines, and sealing machines. This connectivity enables to a fast and continuous packing operations.

The twin-head auger filler may be smoothly incorporated into packaging lines, functioning in tandem with other equipment like conveyor belts, capping machines, and sealing machines. This connectivity enables to a fast and continuous packing operations.

“A twin-head auger filler’s capability” allows for a precise and quick loading of powdered or granular materials into containers. Its capacity is to fill two containers at the same time. Paired with precise metering and control, makes it a great choice for high-speed packing lines where productivity and accuracy are the most vital to it.

Post time: Jun-27-2023