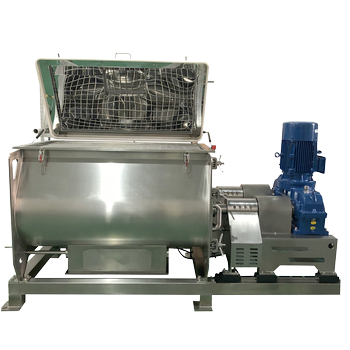

To start off today's topic, let's discuss the paddle mixer manufacturers design.

Paddle mixers come in two varieties; in case you were wondering what their main applications are. Both the double-shaft and single-shaft paddle mixers. A paddle mixer can be used to mix powder and granules with a small amount of liquid. It is extensively used with nuts, beans, seeds, and other granular materials. The material is cross-mixed inside the machine by a blade angled at a varied angle.

Typically, a paddle mixer's design consists of the following portions:

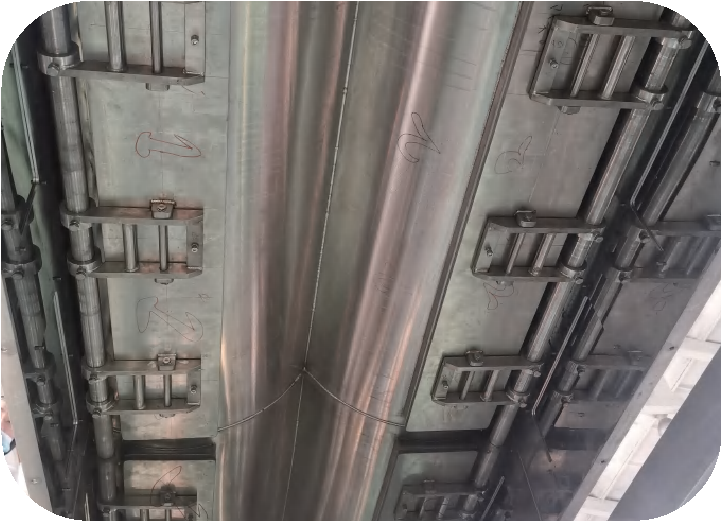

Body:

The mixing chamber, which carries the ingredients to be blended, is the principal component of the paddle mixer. Complete welding is used to join all of the parts, ensuring that no powder is left behind and making cleanup easier after mixing.

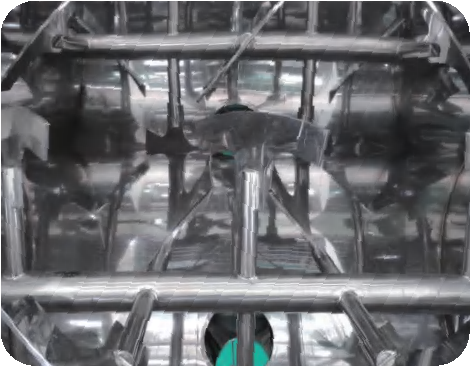

Paddle Agitators:

These devices have highly efficient mixing effects. Paddles throws material from mixing tank bottom to top from different angles.

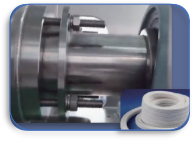

The paddle mixer's shaft and bearings:

It contributes to dependability, easy rotation, and constant performance during the mixing process. Our unique shaft sealing design, which uses the German Burgan packing gland, guarantees a leak-free operation.

Motor Drive:

It is essential because it provides them with the power and control necessary to blend well.

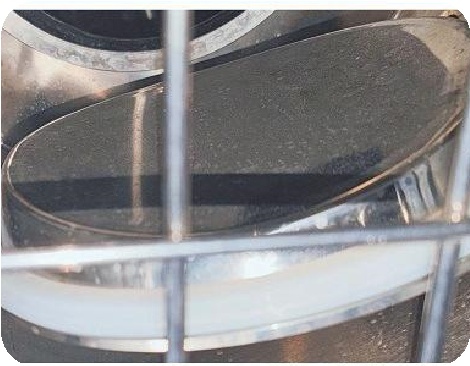

Discharge Valve:

Single shaft paddle mixer: To ensure proper sealing and eliminate any dead angles during mixing, a slightly concave flap is located at the bottom center of the tank. The mixture is poured out of the blender after it has finished mixing.

Double shaft paddle mixer: The discharging hole and the revolving axle will never leak because of the "W"-shaped discharge exit.

Safety Features:

1. Rounded corner design/lid

This design is safer and more advanced. It has a longer useful life, superior sealing, and operator protection.

2. The slow-rising design ensures the longevity of the hydraulic stay bar and protects against cover falls that could put operators in danger.

3. The safety grid protects the operator from the rotating paddle while simplifying the hand loading process.

4. An interlock device ensures worker safety during paddle rotation. The mixer immediately shuts off when the lid is opened.

Post time: Jul-01-2024