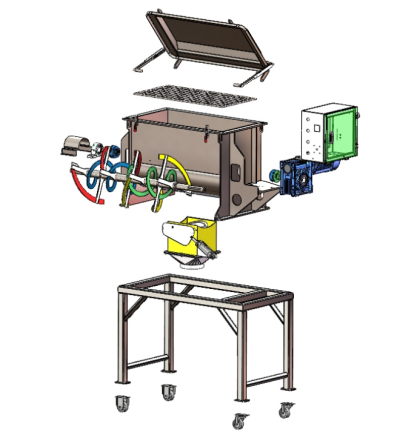

The Ribbon Blender is a widely used mixing device in various industries, renowned for its ability to effectively blend powders and granules. Its design features a U-shaped horizontal trough and a solid mixing shaft, with spiral blades known as ribbons attached to the shaft. This configuration allows the ribbons and shaft to support each other, creating an efficient mixing environment.

Principle of Operation:

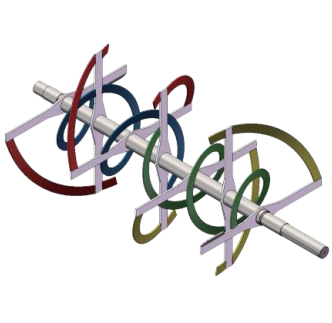

Ribbon Design: The ribbons are designed in a spiral or helical shape, typically with one ribbon moving material from one end of the blender to the other, while the other ribbon moves material in the opposite direction. This dual motion ensures a thorough mix.

Material Flow: The mixing action pushes material to the center of the blender, which is then forced outward by the rotation of the ribbons. This creates a high shear mixing effect that helps achieve a homogeneous blend.

Shear and Mixing: As the ribbons rotate, material is subjected to shear forces. The ingredients move around the trough, ensuring that even materials with different particle sizes and densities can be uniformly mixed.

Batch or Continuous Mixing: Ribbon blenders can operate in both batch or continuous processes, depending on the application and the design of the machine.

Discharge: After the blending process is complete, materials can be discharged via a valve or door at the bottom of the trough.

Principle of Mixing:

At the heart of the ribbon blender’s functionality is its mixing action, driven by a gear motor that rotates the agitator at a peripheral speed of approximately 28 to 46 feet per minute. When the shaft rotates, the ribbon moves the material in a circular motion along the trough, facilitating thorough mixing.

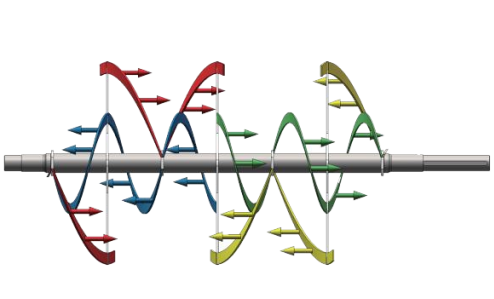

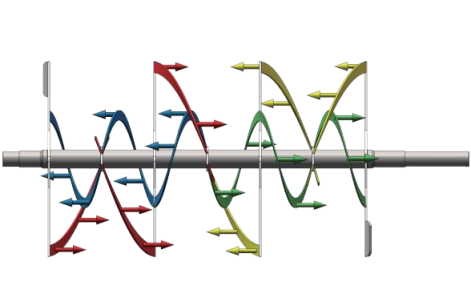

The movement of the ribbons is crucial to the blending process. The outer ribbon pushes the material toward the center of the blender, while the inner ribbon directs it back towards the walls of the trough. This coordinated movement creates a dynamic flow where materials are transported in opposite directions laterally and axially (along the horizontal axis of the blender). As the materials collide within the blender, they generate convection, promoting a homogenous blend.

The ribbon blender achieves two primary mixing actions: radial and bi-axial. Radial mixing involves the movement of material toward the center, while bi-axial mixing facilitates lateral movement. This dual action fosters both small-scale random motion (diffusion) and large-scale random motion (convection), along with shear forces that enhance the mixing process. The ribbon’s rotation effectively pushes materials upward from the bottom of the container, allowing them to flow in the opposite direction at the top, thus establishing a continuous circulation flow. This thorough movement ensures that different types of materials come into full contact with each other, significantly improving mixing uniformity.

If you have any further questions regarding the principle of the ribbon blender, feel free to contact us for consultation. Leave your contact information, and we will proactively reach out to you within 24 hours to assist you and provide answers to your inquiries.

Post time: Mar-06-2025