The Auger filler is a professional design produced by Shanghai Tops Group. We have a high production capacity and advanced auger filler technology. For the appearance of servo auger fillers, we have a patent. This machine can dose and fill. Pharmaceuticals, agricultural, chemical, food, construction, and other industries use auger fillers. It can be used for fine granular materials, low-fluidity materials, and other applications.

Working principle of each type of auger filler:

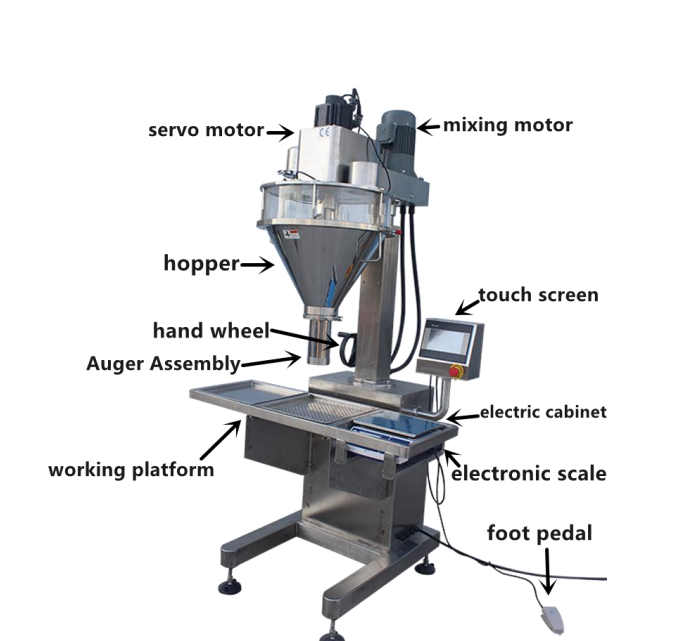

Semi-automatic Auger Filler

The low-speed filling is ideal for the semi-automatic auger filler. Since the operator must manually arrange bottles on a plate under the filler and move them away after filling, it can deal with both bottles and pouches. The hopper can be made entirely of stainless steel. In addition, the sensor might be either a tuning fork sensor or a photoelectric sensor. We offer small auger fillers, standard models, and high-level models of auger fillers for powder.

Semi-automatic Auger Filler with Pouch Clamp

The low-speed filling is ideal for the semi-automatic auger filler. Since the operator must manually arrange bottles on a plate under the filler and move them away after filling, it can deal with both bottles and pouches. The hopper can be made entirely of stainless steel. In addition, the sensor might be either a tuning fork sensor or a photoelectric sensor. We offer small auger fillers, standard models, and high-level models of auger fillers for powder.

Semi-automatic Auger Filler with Pouch Clamp

Line-type Automatic Auger Filler for Bottles

In powder bottle filling, a line-type automatic auger filler is often used. To get an automatic packing line, it can be linked to a powder feeder, powder mixer, capping machine, and labeling machine. The bottle stopper holds back bottles so that the bottle holder can raise the bottle under the filler with the help of the conveyor. After the bottles have been filled, the conveyor automatically moves each bottle forward. It can handle all types of bottle sizes on a single machine and is ideal for users that have multiple packaging dimensions. Optional features include a halted stainless-steel hopper and a full stainless-steel hopper. There are two types of sensors available. It can also be customized to add an online weighing capability for exceedingly high precision.

A high-speed rotary auger filler is used to add the powder to bottles. Because the bottle wheel can only take one diameter, this type of auger filler is best for customers who only have one or two-diameter bottles. The speed and accuracy are greater than those of a line-type auger filler. Furthermore, the rotary type includes online weighing and rejection functions. The filler will load powder as per the filling weight in actual time, and the rejection function will identify and remove disqualified weight. The machine cover is a preference.

Double head auger filler

High-speed filling is achieved using a double-head auger filler. The fastest speed is 100 bpm. Because of the high accuracy weight control, the check weighing and reject system prevents costly product waste. It is commonly used in the manufacturing of milk powder.

When the auger filler is combined with the packing machine, a powder packing machine is formed. It can be used in collaboration with a roll film sachet filling and sealing machine, as well as a micro doypack packing machine, a rotary pouch packing machine, or a premade pouch packing machine.

It is mostly and widely applied as follows:

Semi-automatic Auger Filler is suitable for fluidic or low-fluidity materials like:

Food Industry: coffee powder, wheat flour, condiment, solid drink

Pharmaceutical Industry: veterinary drugs, dextrose, pharmaceuticals,powder additive

Agricultural Industry: agriculture pesticide,and more

Construction industry: talcum powder,and more

Chemical Industry: dyestuff, and more

Semi-automatic Auger Filler with Pouch Clamp is suitable for fluidic or low-fluidity powder and small granular materials like:

Food Industry:instant noodles, flour, proteins, flavors, sweetener, condiment, solid coffee powder, formula milk powder

Pharmaceutical Industry:medicines, beverages, veterinary medications, dextrose

Construction industry: talcum powder,and more

Agricultural Industry: agriculture pesticide,and more

Chemical Industry: dyestuff, and more

Line-type Automatic Auger Filler for Bottles is mostly fluidic or low-fluidity materials, such as:

Food Industry: coffee powder, wheat flour, condiments, solid drinks

Pharmaceutical Industry: veterinary medications, dextrose, powder additives

Construction industry: talcum powder,and more

Agricultural Industry: agriculture pesticide,and more

Chemical Industry: dyestuff, and more

Rotary Automatic Auger Filler is used in fluidic or low-fluidity materials, like:

coffee powder, wheat flour, condiment, solid drink, veterinary drugs, dextrose, pharmaceuticals, powder additive, talcum powder, agriculture pesticide, dyestuff, and so on.

Double head auger filler is commonly used in the manufacturing of milk powder.

Post time: Mar-17-2022