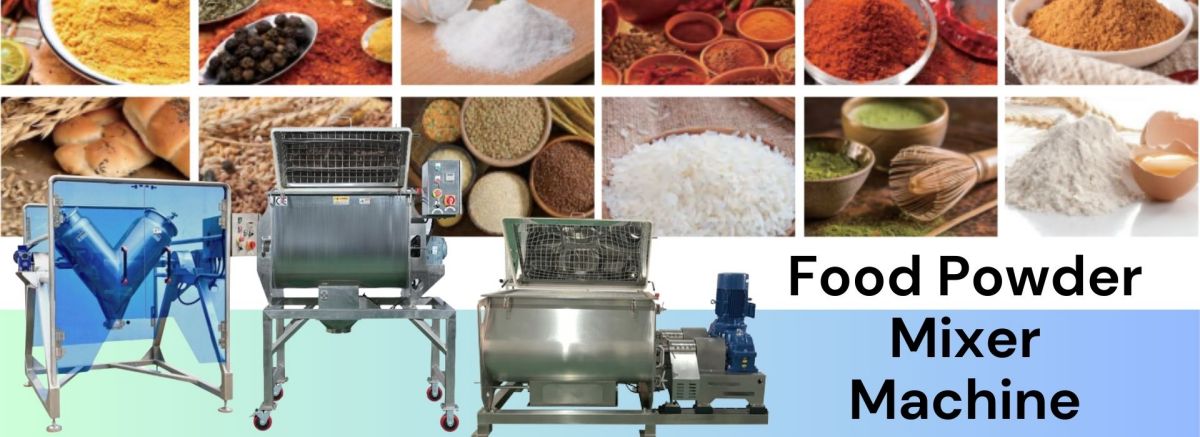

For your food powder business, you can use a variety of machinery. These machines are capable of mixing ingredients to produce a homogenous mixture for use in the food processing industry. The primary function of these machines is to blend powdered substances, including flour, baking powder, salt, sugar, spices, and other powdered components used in food preparation.

These are the food powder mixer machines from which to select:

Ribbon Mixer:

Different powders, powder with liquid spray, and powder with granules are mixed with it. Highly effective convective mixing of the material is achieved quickly by the double-helix ribbon blender as it is propelled by a motor. Material is brought from the sides to the center via the outer ribbon. The material is pushed outward from the center by the inner ribbon.

Paddle Mixer: Single shaft paddle mixer and double shaft paddle mixer

- A single-shaft paddle mixer works well for blending powder and powder, granule and granule, or adding a small amount of liquid. It is frequently used for nuts, beans, and other granule materials. The machine's internal blades are angled differently, which causes the material to be cross-mixed. Material is thrown from the bottom of the mixing tank to the top by paddles at various angles.

- With two shafts and counter-rotating blades, the double-shaft paddle mixer creates two strong upward product flows that create a zone of weightlessness and vigorous mixing. It is frequently used to mix powder and powder, granular and granular, granular and powder, and a small amount of liquid. Paddles with different angles can throw materials from different angles with good mixing effects and high efficiency.

V-Shaped Mixer:

The two cylinders that make up the V blender are arranged in a V shape. It consists of a control panel system, plexiglass door, frame, mixing tank, and other parts. Materials continually cluster and scatter as a result of the gravitate mix created by the two symmetric cylinders. With each rotation of the blender, the product in the two cylinders travels toward the center common area, resulting in a V blender mixing uniformity of more than 99%. This procedure is repeated continuously. Everything in the chamber will be thoroughly mixed.

Multiple types of food powder mixer machines exist. The capacity and volume to be mixed, together with the optimal fit for the type of material, are all important considerations. Tops Group guarantees that every piece of equipment is top-notch and that it is tested thoroughly before being delivered. What are you waiting for? inquire now!

Post time: Apr-10-2024