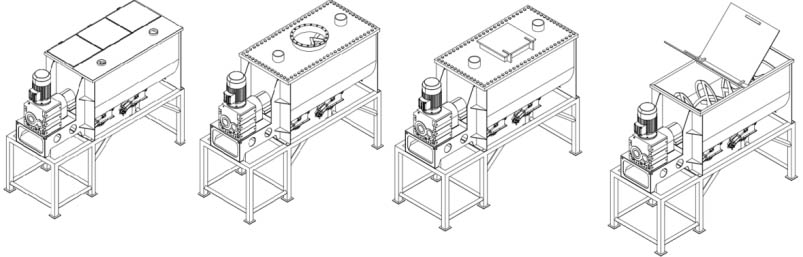

What are the essential components of a ribbon blender?

As you can see, ribbon blenders have a minimalist but adaptable design. The machinery is able to achieve a homogenous blend by using a variety of components. Now let's talk about ribbon blender parts, the major focus of this blog.

1.Top cover

One of the most important ribbon blender components is the top cover, since the materials that ribbon blenders, mix are fed from the top of the machine itself. There are several different designs for the Tops Group top cover design. It is adaptable; you can choose to have a personalized LID for the feeding hopper and more. Using it is safeguarded.

2.U-Shape Tank

A ribbon blender's tank is its main part. That is the precise spot for the mixing procedure. The ribbon blender's tank is composed of 304/316 stainless steel, and its contents are compliant with industry standards. For enhanced mixing, the inner is completely welded and polished.

The most prevalent kind used in ribbon blenders is the U-shaped tank. Since the ribbon blender is so versatile, it is also feasible to set up choppers on the tank in order to mix effectively and efficiently.

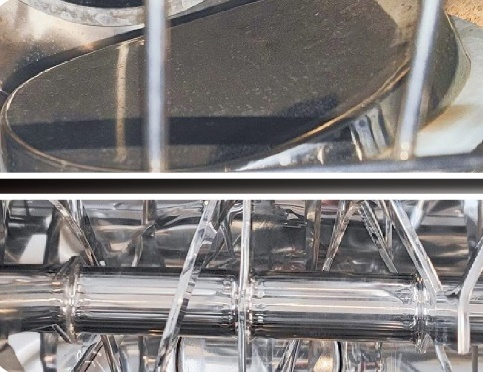

3.Ribbon agitator

The ribbon blender's design revolves around the ribbon agitator. The agitator, one of the key components of a ribbon blender, is made up of a revolving shaft and a set of ribbons, which are a collection of inner and outer helical blades.

Materials are moved from the tank's ends to its center by the agitator's outer ribbons, and vice versa by its inner ribbons. Together, these blades guarantee consistent mixing.

Short processing times allow for the quick achievement of a homogenous blend due to the well-balanced radial and axial movements.

Here's some advice for anyone seeking a high-quality ribbon blender. It is important to carefully manage the distance between the ribbon edges and the tank surface.

4.Discharge valve

The blends were removed from the tank using the ribbon blender discharge valve. It carefully assesses and sets your ribbon blender's discharge rate.

A high-quality discharge valve can swiftly release your blended product. Additionally, it facilitates batch cleaning for your ribbon blender. Also, the discharge valve ensures a tight seal, preventing the contents from leaking out while mixing.

5.Motor Drive

In automatic systems, the drive motor is essential. It is used to convert mechanical motion from electrical energy.

Usually, drives are used to power ribbon blenders. A gearbox, couplings, and a motor make up the driving system.

The most trustworthy drive design for a ribbon blender is a gear motor. It requires less upkeep and is quieter as well. A gear motor and a VFD work well together.

6.Electric control Panel

In general, a number of electrical parts are kept in the control panel. The parts send out signals to control how machinery and other equipment operate. It's among the most important components of a ribbon blender.

Operators can adjust the blender's settings and switch its operation on and off using the control panel. The power indication, start/stop, discharge on/off, emergency stop, and batch time setting timer buttons are the fundamental components of a ribbon blender control panel.

Post time: Aug-28-2024