In this blog, I’ll explain how a horizontal ribbon mixer works, and here’s how it works:

What is horizontal ribbon mixer?

In all process applications, from food to pharmaceutical, agricultural, chemicals, polymers, and more, the horizontal ribbon mixer is one of the most efficient, cost-effective, and generally used to mix different powders, powder with liquid, and powder with granules in dry solids mixers. It’s a multifunctional mixing machine with constant performance, low noise, and high durability.

The main features are as follows:

● The ribbon and shaft, as well as the inside of the tank, are flawlessly mirror polished.

● All the components are properly welded.

● Stainless steel 304 is used throughout and can also be made of 316 and 316L stainless steel.

● Safety features include a safety switch, a grid, and wheels.

● When mixing, there are no dead angles.

● The horizontal ribbon mixer can be set to a high speed to quickly mix the materials.

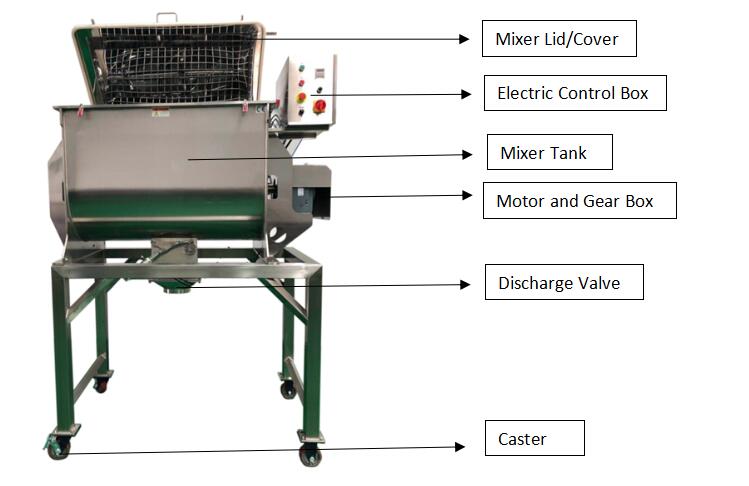

Structure of a horizontal ribbon mixer:

Here’s the working principle:

In this horizontal ribbon mixer, transmission parts, twin ribbon agitators, and a U-shaped chamber are all composed of stainless steel. An inner and outer helical agitator compose a ribbon agitator. The outer ribbon transports materials in one direction, while the inner ribbon transports materials in the opposite direction. The ribbons revolve to move the ingredients radially and laterally, ensuring that the mixes are achieved in a short cycle time. All the connection parts are completely welded. When the combination is generated by all 304 stainless steel, there is no dead angle, and it is easy to clean, maintain, and use.

Hopefully you can get an idea from this blog about the working principle of the horizontal ribbon mixer.

Post time: Feb-18-2022