-

4 Heads Auger Filler

A 4-head auger filler is a economic type of packaging machine used in the food, pharmaceutical, and chemical industries to high accurate measure and fill dry powder, or small granular products into containers such as bottles, jars.

It consists of the 2 sets of double filling heads, an independent motorized chain conveyor mounted on a sturdy and stable frame base, and all necessary accessories to reliably move and position containers for filling, dispense the required amount of product, then quickly move the filled containers away to other equipment in your line (e.g., capping machine, labeling machine, etc.). It fits more to the fluidity or low-fluidity materials, like milk powder, albumen powder, pharmaceuticals, condiment, solid drink, white sugar, dextrose, coffee, agriculture pesticide, granular additive, and so on.

The 4-head auger filling machine is compact model which takes very little space, but the filling speed is 4 times than single auger head, greatly improves the filling speed. It has one comprehensive control system. There are 2 lanes , each lane has 2 filling heads which can do 2 independent fillings.

-

TP-A Series Vibrating linear type weigher

The Linear Type Weigher offers advantages such as high speed, high accuracy, long-term stable performance, favorable pricing, and excellent after-sales service. It is suitable for weighing sliced, rolled, or regularly shaped products, including sugar, salt, seeds, rice, sesame, glutamate, coffee beans, seasoning powders, and more.

-

Semi-automatic Big Bag Auger Filling Machine TP-PF-B12

The large bag powder filling machine is a high-precision industrial equipment designed for efficiently and accurately dosing powders into large bags. This equipment is highly suitable for large bag packaging applications ranging from 10 to 50kg, with filling driven by a servo motor and accuracy ensured by weight sensors, delivering precise and reliable filling processes.

-

ECONOMIC AUGER FILLER

The auger filler can fill powder to bottles and bags in quantity. Due to the special professional design, so it is suitable to the fluidic or low-fluidity

materials, like coffee powder, wheat flour, condiment, solid drink, veterinary drugs, dextrose, pharmaceuticals, powder additive, talcum powder,

agriculture pesticide, dyestuff, and so on. -

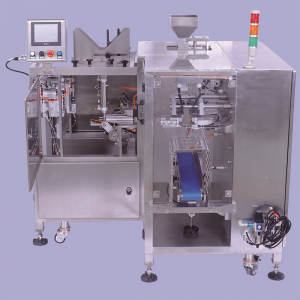

Automatic Auger Filler

This Machine is a complete, economical solution to your filling production line requirements.can measuring and filling powder and granular. It consists of the Filling Head, an independent motorized chain conveyor mounted on a sturdy, stable frame base, and all necessary accessories to reliably move and position containers for filling, dispense the required amount of product, then quickly move the filled containers away to other equipment in your line (e.g., cappers, labelers, etc.).it fits more to the fluidic or low-fluidity materials, like milk powder, albumen powder, pharmaceuticals, condiment, solid drink, white sugar, dextrose, coffee, agriculture pesticide, granular additive, and so on.

-

The Semi-Auto Powder Filling Machine

Are you searching for a powder filler for both household and commercial use? Then we have everything you require. Continue reading!

-

Semi-Automatic Auger Filling Machine

This is Semi-Automatic model of Auger Filler. It is a type of Packaging Equipment used for dispensing powder or granular materials. It employs an auger conveyor to accurately distribute the material into containers or bags, widely used in industries such as food, pharmaceuticals and chemicals.

· Accurate Dosing

· Wide Application Range

· User-Friendly Operation

· Consistency and Reliability

· Hygienic Design

· Versatility

-

Double Shaft Paddle Mixer

Double shaft paddle mixer is called no gravity mixer, too; it is widely applied in mixing powder and powder, granular and granular, granular and powder, and few liquid; it is used for food, chemical, pesticide, feeding stuff, and battery etc.

-

Screw Conveyor

This is standard model of screw conveyor (also known as an auger feeder) is a type of equipment used for material handling, commonly employed to transport powders, granules, and small bulk materials. It utilizes a rotating helical screw blade to move materials along a fixed tube or trough to a desired location. This equipment is widely used in industries such as agriculture, food processing, pharmaceuticals, chemicals, and construction materials.

-

Single Shaft Paddle Mixer

The single shaft paddle mixer is suitable use for powder and powder, granule and granule or add a little liquid to mixing, it is widely applied in nuts ,beans ,fee or other kinds of granule material ,inside of the machine have different angle of blade thrown up the material thus cross mixing.

-

Automatic Bag Packaging machine

Bagged products can be seen everywhere in our life, do you know how to pack these product into the bags? In addition to manual, semi-automatic filling machine, most of the bagging products are fully automatic packaging machine to achieve packaging.

Fully automatic bag packaging machine can complete bag opening, zipper opening , filling, heat sealing function. It widely used in many fields such as food industry, chemical industry, pharmaceutical Industry, agricultural industry, cosmetics industry etc.

-

Capping bottle Machine

Capping bottle Machine is economical, and easy to operate. This versatile in-line capper handles a wide range of containers at speed up to 60 bottles per minute and offers a quick and easy changeover that maximizes production flexibility. The cap pressing system is gentle which will not damage caps but with an excellent capping performance.