We the Tops Group Co., LTD. is a professional packaging machine supplier that specialize in the fields of designing, manufacturing, supporting, and servicing a complete line of machinery for different types of liquid, powder, and granular products. We utilized in the production of agriculture industry, chemical industry, food industry, and pharmacy fields, and many more. We are commonly known for its advanced design concept, professional technique support and high quality machines.

Tops-Group looks forward to provide you with amazing service and exceptional products of machines. All together let’s create long term valued relationship and build a successful future.

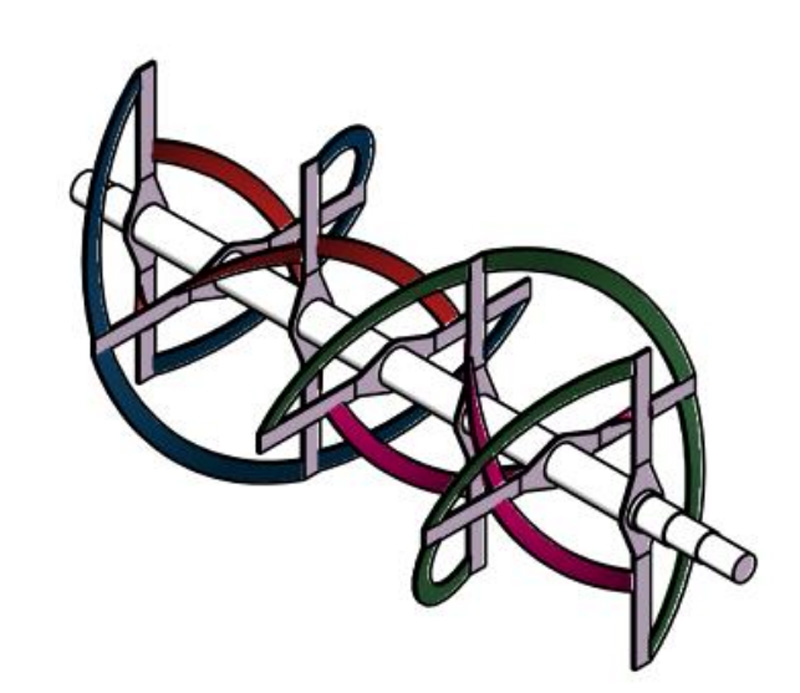

Working Principle

This stainless steel horizontal ribbon mixer is made up of transmission parts, twin ribbon agitators, and a U-shaped chamber. A ribbon mixer agitator is made up of an inner and outer helical agitator. The outer ribbon moves materials one way, while the inner ribbon moves materials the other way. The ribbons rotate approximately to move the materials both radially and laterally to ensure the blends in short cycle times. All connection parts of powder ribbon mixer are fully welded. No dead angle when mixture is generated by all 304 stainless steel ribbon mixer materials and it is easy to clean and easy to use.

Main Features

• Inside the tank of powder ribbon mixer is a complete mirror polished as well as ribbon and shaft.

• All parts of ribbon mixer are fully welded.

• Ribbon mixer is made up of stainless steel 304 material and can also be made of 316 and 316 L stainless steel.

• Ribbon mixer has a safety switch, grid and wheels for safety using.

• Powder ribbon mixer has patent technology on shaft sealing and discharge design.

• The ribbon mixer can be adjusted into high speed for mixing the materials within a short time.

Specifications

|

Model |

TDPM 100 |

TDPM 200 |

TDPM 300 |

TDPM 500 |

TDPM 1000 |

TDPM 1500 |

TDPM 2000 |

TDPM 3000 |

TDPM 5000 |

TDPM 10000 |

|

Capacity (L) |

100 |

200 |

300 |

500 |

1000 |

1500 |

2000 |

3000 |

5000 |

10000 |

|

Volume (L) |

140 |

280 |

420 |

710 |

1420 |

1800 |

2600 |

3800 |

7100 |

14000 |

|

Loading rate |

40%-70% |

|||||||||

|

Length (mm) |

1050 |

1370 |

1550 |

1773 |

2394 |

2715 |

3080 |

3744 |

4000 |

5515 |

|

Width (mm) |

700 |

834 |

970 |

1100 |

1320 |

1397 |

1625 |

1330 |

1500 |

1768 |

|

Height (mm) |

1440 |

1647 |

1655 |

1855 |

2187 |

2313 |

2453 |

2718 |

1750 |

2400 |

|

Weight (kg) |

180 |

250 |

350 |

500 |

700 |

1000 |

1300 |

1600 |

2100 |

2700 |

|

Total Power (KW) |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

18.5 |

22 |

45 |

75 |

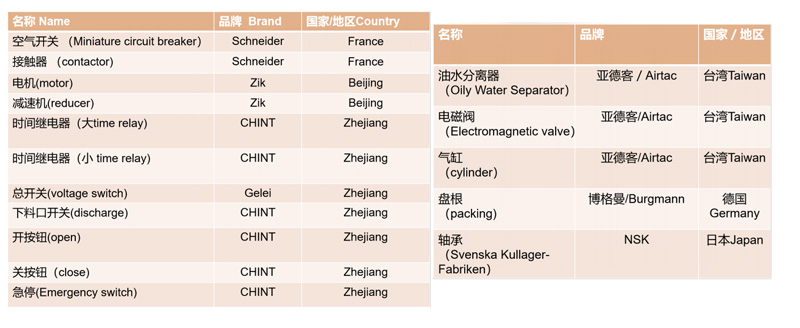

Accessories list

Mirror polished

Powder blender has a complete mirror polished into a tank and also a special ribbon and shaft design. Also powder blender has the design that contains concave pneumatically controlled flap at the center of the bottom of the tank to ensure a better sealing, no leakage, and no dead mixing angle.

Hydraulic strut

Powder blender has hydraulic strut and to make hydraulic stay bar long life it keeps slowly rising. Both materials can be combined to create the same product or part as options for SS304 and SS316L.

Silicone ring

Powder blender has silicone ring that can prevent dust coming out from mixing tank. And it’s easy to clean. All material is stainless steel 304 and can also be made of 316 and 316 L stainless steel.

Safety Grid

The powder ribbon mixer has three safety devices functions: for safety, protection for the operator to avoid personnel injury from mixing material in powder ribbon mixer. To prevent from foreign substance that falls into a tank. Example, when you load with a big bag of materials in ribbon mixer it prevents the bag to fall into a mixing tank.

The powder ribbon mixer has a grid that can break with a large caking of your product that falls into the tank. Full mirror polished inside of mixing tank, as well as ribbon and shaft, easy to clean as full welding. The ribbon mixer has also patent technology on shaft sealing and discharge design. No need to worry about the screw falling into material and contaminating the material inside the tank of powder ribbon mixer. Based on the product and mixing volume, the ribbon mixer can be set from 1 to 15 minutes.

Optional:

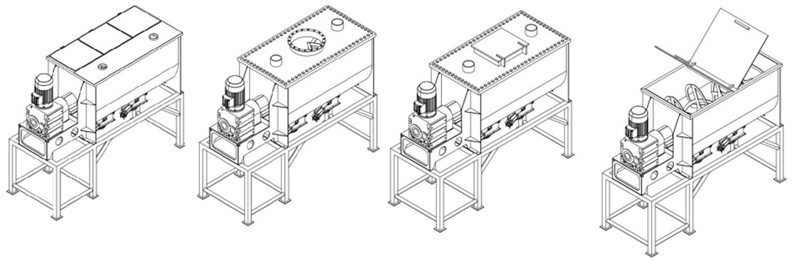

A. Barrel Top Cover

-The top cover of ribbon mixer can also be customized and the discharge valve can be manually or pneumatically driven.

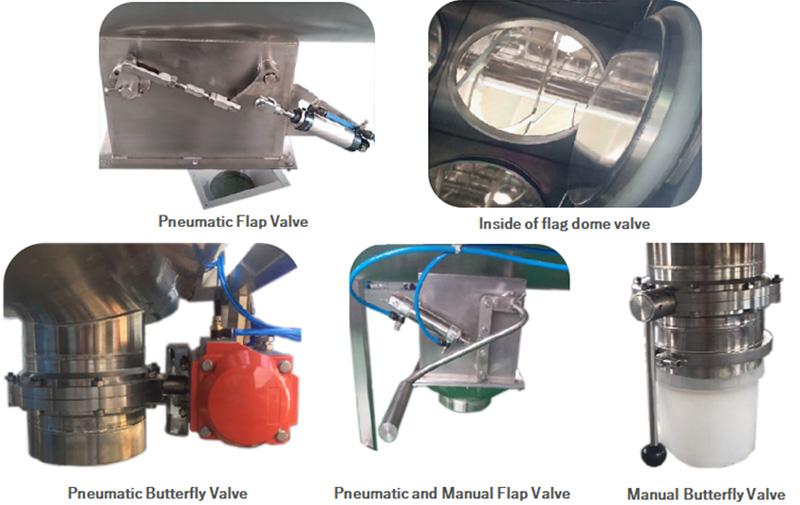

B. Types of valve

-The ribbon mixer has optional valves: cylinder valve, butterfly valve and etc.

C. Additional Functions

The ribbon mixer can also customize and customer can also require the ribbon mixer to equipped additional function with a jacket system for heating and cooling system, weighing system, dust removal system and spray system. The ribbon mixer has a spraying system for liquid to blend in a powder material. This powder ribbon mixer has the cooling and heating function of a double jacket and it could be intended to keep the mixing material warm or cold.

D. Speed Adjustment

-Ribbon mixer can also customize speed adjustable, by installing a frequency converter; the powder ribbon mixer can be adjusted to the speed.

Load system

Ribbon Mixer has automated loading and there are three types of transporter, the vacuum loading system is better suited for loading at high height, while screw feeder is not suited for granule or easy-break material however it is suitable for working shops which have limited height and the bucket conveyor is suitable for granule conveyor. The ribbon mixer is best suited for powders and materials with a high or low density, and it requires more force during mixing.

In comparison with manual operation, the production line saves a lot of energy and time. In order to supply enough material in due time, the loading system will connect two machines. The machine manufacturer tells you that it takes you less time and improves your efficiency. A lot of industries involved in the food, chemical, agricultural, comprehensive, battery and other industries are using powder ribbon mixers.

Production and Processing

Factory Shows

Service & Qualifications

■ Provide accessory parts in favorable price

■ Update configuration and program regularly

■ Respond to any question in 24 hours

■ Payment Term: L/C, D/A, D/P, T/T, Western Union, Money Gram, PayPal

■ Price Term: EXW, FOB, CIF, DDU

■ Package: cellophane cover with wooden case.

■ Delivery Time: 7-10 days (standard model)

30-45days (customized machine)

■ Note: Powder blender shipped by air is about 7-10 days and 10-60 days by sea, it depends on a distance.

■Place of Origin: Shanghai China

■Warranty: One-year warranty, life-long service

Powder blender completion

And now you recognize what a powder blender is used for. How to use, who to use, what parts are there, what materials are used, what sort of design is there, and how efficient, effective, useful, and easy this powder blender to use.

If you have questions and inquiries feel free to contact us.

Tel: +86-21-34662727 Fax: +86-21-34630350

E-mail: wendy@tops-group.com

THANK YOU AND WE LOOK FORWARD

TO ANSWER YOUR INQUIRY!