Product Description

The screw feeder efficiently and conveniently transfers powder and granule materials between machines. It can collaborate with packing machines to create a production line, making it a widely used feature in packaging lines, especially in semi-automatic and automatic packaging processes. This equipment is primarily utilized for conveying powder materials, such as milk powder, protein powder, rice powder, milk tea powder, solid beverage, coffee powder, sugar, glucose powder, food additives, feed, pharmaceutical raw materials, pesticides, dyes, flavors, and fragrances.

Application

Description

Bottle Capping Machine is an automatic capping machine to press and screw lids on bottles. It’s special designed for automatic packing line. Different to traditional intermittent type capping machine, this machine is a continuous capping type. Compared to intermittent capping, this machine is more efficient, pressing more tightly, and do less harm to the lids. Now it’s widely applied in food, pharmaceutical,agriculture, chemical,

cosmetics industries.

Features

1.Hopper is vibratory which makes material to flow down easily.

2.Simple structure in linear type ,easy in installation and maintenance.

3.The whole machine is made of SS304 to reach the food grade request.

4.Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

5.High pressure double crank to control the die opening and closing.

6.Running in a high automation and intelligentialize,no pollution

7.Apply a linker to connect with the air conveyor ,which can directly inline with filling machine.

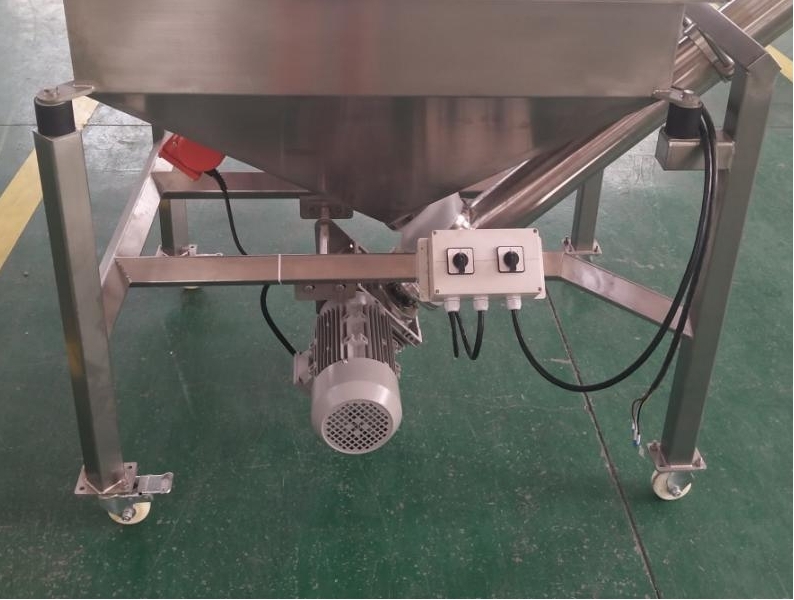

Details

C.Two motors: one for screw feeding, one for hopper’s vibrating.

D.The conveying pipe is stainless steel 304, full weld and full mirror polishing. It is easy to clean, and no blind area to hide material.

E. The residue discharge port with a door at the bottom of the tube, makes it easy to clean the residue without dismantle it.

F. Two switches on the feeder. One to turn the auger, one to vibrate the hopper.

G. The holder with wheels makes the feeder movable to accommodate the production better.

Specification

| Main Specification | HZ-2A2 | HZ-2A3 | HZ-2A5 |

HZ-2A7 |

HZ-2A8 |

HZ-2A12 |

|

| Charging Capacity | 2m³/h | 3m³/h | 5m³/h | 7m³/h | 8m³/h | 12m³/h | |

| Diameter of pipe | Φ102 | Φ114 | Φ141 | Φ159 | Φ168 | Φ219 | |

| Hopper Volume | 100L | 200L | 200L | 200L | 200L | 200L | |

| Power Supply | 3P AC208-415V 50/60HZ | ||||||

| Total Power | 610W | 810W | 1560W | 2260W | 3060W | 4060W | |

| Total Weight | 100kg | 130Kg | 170Kg | 200Kg | 220Kg | 270Kg | |

| Overall Dimensions of Hopper | 720×620×800mm | 1023×820×900mm | |||||

| Charging Height |

Standard 1.85M,1-5M could be designed and manufactured |

||||||

| Charging angle |

Standard 45 degree ,30-60 degree are also available |

||||||

Production and Processing

About Us

Shanghai Tops Group Co., Ltd is professional manufacturer for powder and granular packaging systems.

We specialize in the fields of designing, manufacturing, supporting and servicing a complete line of machinery for different kinds of powder and granular products, Our main target of working is to offer the products which are related to the food industry, agriculture industry, chemical industry, and pharmacy field and more.

We value our customers and are dedicated to maintaining relationships to ensure continued satisfaction and create win-win relationship. Let’s work hard altogether and make much greater success in the near future!

Factory Show

Our Team

Our Certification

FAQ

Q1: What types of materials can a screw conveyor handle?

A1: Screw conveyors are suitable for transporting a wide range of materials, including powders, granules, small pieces, and even some semi-solid materials. Examples include flour, grains, cement, sand, and plastic pellets.

Q2: How does a screw conveyor work?

A2: A screw conveyor works by using a rotating helical screw blade (auger) inside a tube or trough. As the screw rotates, material is moved along the conveyor from the inlet to the outlet.

Q3: What are the advantages of using a screw conveyor?

A3: Advantages include:

- Simple and robust design

- Efficient and controlled material transport

- Versatility in handling different materials

- Customizable for specific applications

- Minimal maintenance requirements

- Sealed design to prevent contamination

Q4: Can a screw conveyor handle wet or sticky materials?

A4: Screw conveyors can handle some wet or sticky materials, but they may require special design considerations such as coating the screw blade with non-stick materials or using a ribbon screw design to minimize clogging.

Q5: How do you control the flow rate in a screw conveyor?**

A5: The flow rate can be controlled by adjusting the rotation speed of the screw. This is typically done using a variable frequency drive (VFD) to change the motor speed.

Q6: What are the limitations of screw conveyors?

A6: Limitations include:

- Not suitable for very long-distance transport

- Can be prone to wear and tear with abrasive materials

- May require more power for high-density or heavy materials

- Not ideal for handling fragile materials due to potential for breakage

Q7: How do you maintain a screw conveyor?

A7: Maintenance involves regular inspection and lubrication of the bearings and drive components, checking for wear on the screw blade and tube, and ensuring that the conveyor is clean and free of blockages.

Q8: Can a screw conveyor be used for vertical lifting?

A8: Yes, screw conveyors can be used for vertical lifting, but they are typically referred to as vertical screw conveyors or screw elevators. They are designed to move materials vertically or at steep inclines.

Q9: What factors should be considered when selecting a screw conveyor?

A9: Factors to consider include the type and properties of the material to be transported, the required capacity, the distance and angle of transport, the operating environment, and any specific requirements such as sanitation or corrosion resistance.