Characteristics

●Precision auger screw for accurate filling

●PLC control and touchscreen display

●Servo motor ensures stable performance

●Quick-disconnecting hopper for easy tool-free cleaning

●Start filling with pedal or switch

●Made of full stainless steel 304

●Weight feedback and proportion tracking to accommodate changes in filling weight due to material density

●Stores up to 10 formulas for future use

●Can pack different products, from fine powder to tiny granules, by replacing auger parts and adjusting weight

●Bag clamp equipped with a weight sensor for fast and slow filling to ensure high packaging

accuracy

●Process: Place the bag under the bag clamp → Raise the bag → Fast filling, container declines → Weight reaches the preset value → Slow filling → Weight reaches the target value → Manually remove the bag

Technical Parameter

| Model | TP-PF-B12 |

| Control system | PLC & Touch Screen |

| Hopper | Quick disconnecting hopper 100L |

| Packing Weight | 10kg – 50kg |

| Dosing mode | With online weighing; Fast and slow filling |

| Packing Accuracy | 10 – 20kg, ≤±1%, 20 - 50kg, ≤±0.1% |

| Filling Speed | 3– 20 times per min |

| Power Supply | 3P AC208-415V 50/60Hz |

| Total Power | 3.2 KW |

| Total Weight | 500kg |

| Overall Dimensions | 1130×950×2800mm |

Configuration List

| No. | Name | Pro. | Brand |

| 1 | Touch Screen | Germany | Siemens |

| 2 | PLC | Germany | Siemens |

| 3 | Servo Motor | Taiwan | Delta |

| 4 | Servo Driver | Taiwan | Delta |

| 5 | Load Cell | Switzerland | Mettler Toledo |

| 6 | Emergency Switch | France | Schneider |

| 7 | Filter | France | Schneider |

| 8 | Contactor | France | Schneider |

| 9 | Relay | Japan | Omron |

| 10 | Proximity Switch | Korea | Autonics |

| 11 | Level Sensor | Korea | Autonics |

Details

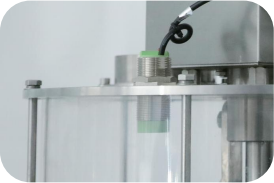

1. HOPPER

Level split hopper

It is very easy to open hopper and it is also easy for cleaning.

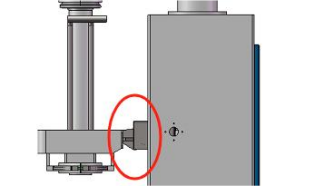

2. SCREW TYPE

The way to fix auger screw

The material will not be stocked and is easy to clean.

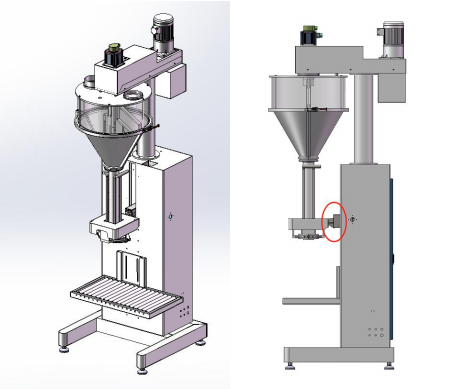

3. PROCESSING

All hardware connections of the hopper are fully welded for easy cleaning.

Six. Packing System

4. AIR OUTLET

Stainless steel type

The assembly and disassembly are simple and convenient, making it easy to clean.

Five. Configuration

5. LEVEL SENSOR

(AUTONICS)

When the material level inside the hopper is insufficient, world famous brand sensor

automatically sends a signal to the loader for automatic material feeding.

6. BAG CLAMP

Safety design clamp

The bag-clamping shape design ensures a firmer grip on the bag. The operator

manually triggers the bag-clamping switch to ensure safety.

7. CONTROL

Siemens brand with warning

World-renowned brand PLC and

touchscreen enhance system stability. Warning lights and buzzers prompt

operators to inspect alarms.

8. STABLE LIFTING

Synchronous belt drive

Elevator system with synchronous belt drive ensures stability, durability, and consistent speed.

9. LOAD CELL

(Mettler Toledo)

World-renowned brand of weight sensors, providing 99.9% high-precision filling. The special placement ensures that weighing is not affected by the lifting.

10. ROLLER CONVEYOR

Easy moving

The roller conveyor makes it easier for operators to move the filled bulk bags.

Drawing

Related Machines

Screw Feeder+Horizontal Mixer with Platform+Vibration Sieve+Screw Feeder+Big Bag Filling Machine+Bag Sealing Machine+Bag Seaming Machine