Short Lead Time for Wheat Mixer - Double shaft paddle mixer – Shanghai Tops Detail:

Descriptive abstract

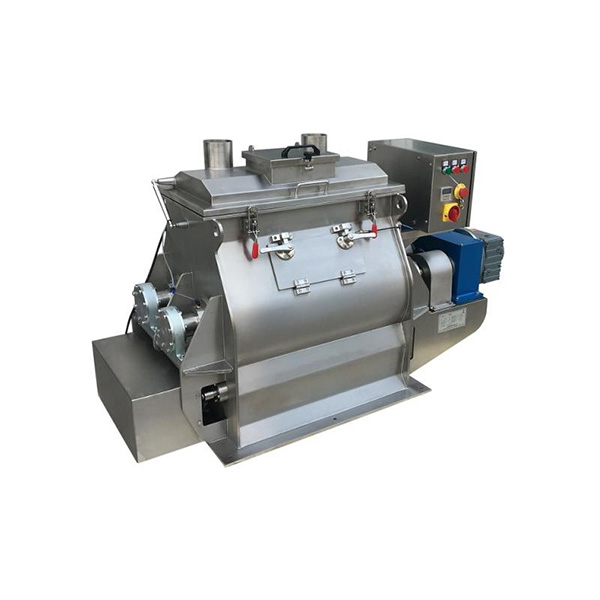

Double shaft paddle mixer is provided with two shafts with counter-rotating blades, which produce two intense upward flows of product, generating a zone of weightlessness with an intense mixing effect. It is widely applied in mixing powder and powder, granular and granular, granular and powder, and few liquid; especially for those with a fragile morphology that need to be respected.

Main features

1. High active: Rotate reversely and throw materials to different angles,mixing time 1-3min.

2. High uniformity: Compact design and rotated shafts be filled with hopper, mixing uniformity up to 99%.

3. Low residue: Only 2-5mm gap between shafts and wall, open-type discharging hole.

4. Zero leakage: Patent design and ensure the rotating axle & discharging hole w/o leakage.

5. Full clean: Full weld and polishing process for mixing hopper, w/o any fastening piece like screw,nut.

6. Nice profile: the whole machine is made by 100% stainless steel to make its profile elegant except bearing seat.

7. Capacities from 100 up to 7.500 liters.

Options

■ Internally mirror polished Ra ≤ 0.6 µm (Grit 360).

■ Externally polished in matte or mirror.

■ Liquid injection by spraying.

■ Choppers for mixing intensification and lump breaking.

■ CIP system on demand.

■ Heating/cooling jacket.

■ RYOGENIC execution.

■ Automatic loading and unloading systems as an option.

■ Solids loading and dosing systems.

■ Weighting systems.

■ “Continuous” formulation system installations.

■ Packing systems for mixed products.

Main technical data

| Model | TPW-300 | TPW-500 | TPW-1000 | TPW-1500 | TPW-2000 | TPW-3000 |

| Effective volume(L) | 300 | 500 | 1000 | 1500 | 2000 | 3000 |

| Full volume(L) | 420 | 650 | 1350 | 2000 | 2600 | 3800 |

| Loading Ratio | 0.6-0.8 | |||||

| Turning speed(rpm) | 53 | 53 | 45 | 45 | 39 | 39 |

| power | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 |

| Total weight(kg) | 660 | 900 | 1380 | 1850 | 2350 | 2900 |

| Total size | 1330*1130 *1030 |

1480*135 0*1220 |

1730*159 0*1380 |

2030*1740 *1480 |

2120*2000 *1630 |

2420*230 0*1780 |

| R(mm) | 277 | 307 | 377 | 450 | 485 | 534 |

| Power supply | 3P AC208-415V 50/60Hz | |||||

Detailed pictures

Double shaft paddle: paddles with different angles can threw materials from different angles, very good mixing effect and high efficiency.

Safety grid to avoid personnel injury.

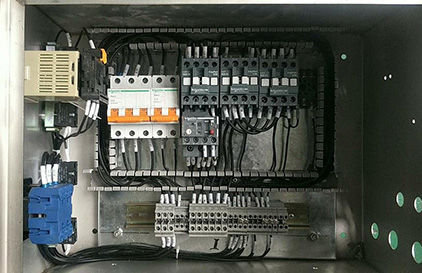

Electric control box

Famous component brand: Schneider & Omron

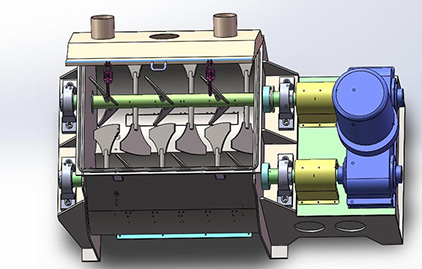

Three dimensional figure

Related mixing machine that our company also manufacture

Single shaft paddle mixer

Open type double paddle mixer

Double ribbon mixer

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for Short Lead Time for Wheat Mixer - Double shaft paddle mixer – Shanghai Tops, The product will supply to all over the world, such as: Malaysia, Albania, Birmingham, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We've got established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance might be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.

-

professional factory for Wheat Mixer Machine Pr...

-

Best High Quality Chilli Powder Packing Machine...

-

China Wholesale Dry Powder Filler Factory ̵...

-

China Wholesale Auger Filling Machines Manufact...

-

China Wholesale Auger Powder Filler Factories &...

-

Chinese wholesale Horizontal Ribbon Mixer - Do...