APPLICATION

This machine is commonly used in dry solid blending materials and used in the following application:

• Pharmaceuticals: mixing prior to powders and granules.

• Chemicals: metallic powder mixtures, pesticides and herbicides and many more.

• Food processing: cereals, coffee mixes, dairy powders, milk powder and many more.

• Construction: steel preblends and etc.

• Plastics : mixing of master batches, mixing of pellets, plastic powders and many more.

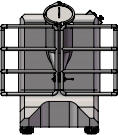

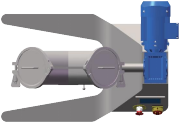

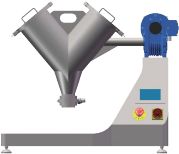

Working Principle

This machine is composed of mixing tank, frame, transmission system, electrical system etc. It relies on two symmetric cylinders to gravitative mix, which makes materials constantly gather and scattered. It takes 5 ~ 15 minutes to mix two or more powder and granular materials evenly. The recommended blender's fill-up volume is 40 to 60% of the overall mixing volume. The mixing uniformity is more than 99% which means that the product in the two cylinders moves into the central common area with each turn of the v mixer, and this process, is done continually.The inner and outer surface of the mixing tank is fully welded and polished with precision processing, which is smooth, flat, no dead angle and easy to clean.

MAIN FEATURES

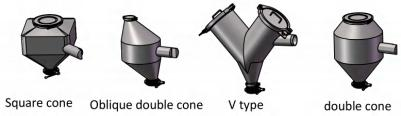

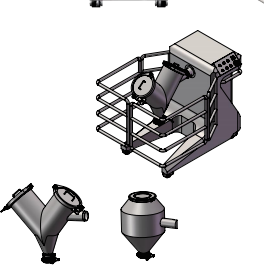

• Adaptablity and flexibility. A single-arm mixer with the choice to swap between tank types (V mixer, double cone.square cone, or oblique double cone) for a wide range of mixing needs.

• Easy cleaning and maintenance. The tanks are designed with an ease of cleaning and maintenance in mind. To easet horough cleaning and prevent material residue, it must be considered to carefully check these features such as removable parts, access panels and smooth, crevice-free surfaces.

• Documentation and Training: Provide a clear documentation and training materials to users to help them through the proper way on operation, tank switching processes, and mixer maintenance. This will ensure that the equipment isused safely and more effectively.

• Motor Power and Speed: Make sure that the motor driving the mixing arm is large and powerful enough to handle the various tank types. Contemplate the various load requirements and desired mixing speeds within each tank type.

Main Technical Data

STANDARD CONFIGURATION

| No. | Item | Brand |

| 1 | Motor | Zik |

| 2 | Stirrer Motor | Zik |

| 3 | Inverter | QMA |

| 4 | Bearing | NSK |

| 5 | Discharge Valve | Butterfly Valve |

DETAILED PHOTOS

The properties of each tank type

(V shape, double cone, square cone, or oblique doublcone) influence mixing performance. Within each tank type, designs the tanks tooptimize material circulation and blending. Tank dimensions, angles, and surface treatments should a be considered to enable efficient mixing and minimize material stagnation or buildup.

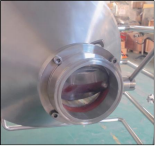

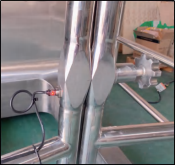

Material inlet and outlet

1.The feeding inlet has movable cover through pressing the lever it is easy to operate

2.Edible silicone rubber sealing strip, good sealing performance, no pollution 3.Made of stainless steel

4.For each tank type, it designs the tanks with correct positioned and sized material inlets and outputs. lt guarantees efficient material loading and unloading, considering the individual requirements of the materials being mixed as well as the required flow patterns.

5.Butterfly valve discharge.

Easy to take down and assemble

Replacing and assembling the tank is convenient and easy and can be done by one person.

Full Welding and Polished inside and outside. Easy to Clean

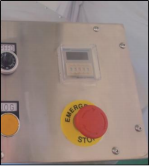

| Safety Measures

This includes such as emergency stop buttons, safety guards, and interlocks should be encompassed to ensure operator safety during tank switching and operation. Safety interlock: Mixer stops automatically when doors open. |

||||

|

||||

Fuma Wheel Makes machine stand stably and can be moved easily.   |

||||

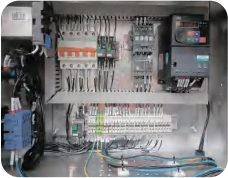

| Control System Integration

It considers of combining the mixer with a controlling system that is capable of handling tank switching. This would include automating the tank swapping mechanism and adjusting mixing settings based on the tank type. |

||||

Compatibility of Mixing Arms lt ensures that the single-arm mixing mechanism is compatible with all tank types. The mixing arm's length,form, and connection mechanism allow for smooth operation and successful mixing within each tank type.  |

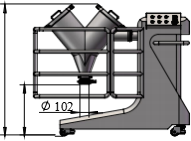

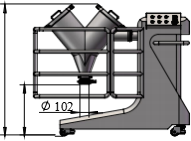

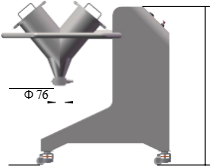

DRAWING

Design parameters of miniature single-arm mixer :

1. suitable volume: 3 0-80L

2. changable tank as folloing

3. power 1.1kw;

4. design turning speed: 0-50 r/min (

stable

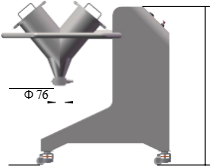

Small size lab mixer:

1.Total volume: 10-30L;

2.Turning speed : 0-35 r/min

3.Capacity : 40%-60% ;

4.Maximum load weight: 25kg ;

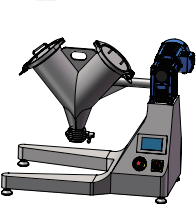

Tabletop Lab V Mixer :

1. total power : 0.4kw ;

2. volume available : 1-10L ;

3. can switch different shape tanks

4. turning speed: 0-24r/min ( adjustable ) ;

5. with frequency converter, PLC , touch screen

CERTIFICATES