The Tops Group offers a variety of semi-auto powder filling machines. We have desktop tables, standard models, high-level designs with pouch clamps, and big bag types. We have a large production capacity as well as advanced auger powder filler technology. We have a patent on the appearance of servo auger fillers.

The Different Types of Semi-Auto Powder Filling Machine

Desktop Type

This is the smallest model for a laboratory table. It is designed specifically for fluidic or low-fluidity materials such as coffee powder, wheat flour, condiments, solid drinks, veterinary medications, dextrose, pharmaceuticals, powder additives, talcum powder, agricultural pesticides, dyestuff, and so on. This type of filling machine can both dose and fill work.

|

Model |

TP-PF-A10 |

|

Control system |

PLC & Touch Screen |

|

Hopper |

11L |

|

Packing Weight |

1-50g |

|

Weight dosing |

By auger |

|

Weight Feedback |

By off-line scale (in picture) |

|

Packing Accuracy |

≤ 100g, ≤±2% |

|

Filling Speed |

40 – 120 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

|

Total Power |

0.84 KW |

|

Total Weight |

90kg |

|

Overall Dimensions |

590×560×1070mm |

The Standard Type

This type of filling is appropriate for low-speed filling. Since it requires the operator to place bottles on a plate beneath the filler and physically remove bottles after filling. It is capable of handling both bottle and pouch packages. The hopper can be made entirely of stainless steel. In addition, the sensor might be either a tuning fork sensor or a photoelectric sensor.

|

Model |

TP-PF-A11 |

TP-PF-A14 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

25L |

50L |

|

Packing Weight |

1 - 500g |

10 - 5000g |

|

Weight dosing |

By auger |

By auger |

|

Weight Feedback |

By off-line scale (in picture) |

By off-line scale (in picture) |

|

Packing Accuracy |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Filling Speed |

40 – 120 times per min |

40 – 120 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

0.93 KW |

1.4 KW |

|

Total Weight |

160kg |

260kg |

|

Overall Dimensions |

800×790×1900mm |

1140×970×2200mm |

With Pouch Clamp Type

This semi-automatic filler with a pouch clamp is ideal for pouch filling. After stamping the pedal plate, the pouch clamp will automatically retain the bag. It will automatically release the bag after filling.

|

Model |

TP-PF-A11S |

TP-PF-A14S |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

25L |

50L |

|

Packing Weight |

1 - 500g |

10 - 5000g |

|

Weight dosing |

By load cell |

By load cell |

|

Weight Feedback |

Online weight feedback |

Online weight feedback |

|

Packing Accuracy |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Filling Speed |

40 – 120 times per min |

40 – 120 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

0.93 KW |

1.4 KW |

|

Total Weight |

160kg |

260kg |

|

Overall Dimensions |

800×790×1900mm |

1140×970×2200mm |

Big Bag Type

Given that it is the largest model, the TP-PF-B12 incorporates a plate that raises and lowers the bag during filling to reduce dust and weight error. Because there is a load cell that detects real-time weight, gravity will lead to inaccuracy when powder is dispensed from the end of the filler to the bottom of the bag. The plate lifts the bag, allowing the filling tube to attach to it. During the filling process, the plate falls gently.

|

Model |

TP-PF-B12 |

|

Control system |

PLC & Touch Screen |

|

Hopper |

100L |

|

Packing Weight |

1kg – 50kg |

|

Weight dosing |

By load cell |

|

Weight Feedback |

Online weight feedback |

|

Packing Accuracy |

1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

|

Filling Speed |

2– 25 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

|

Total Power |

3.2 KW |

|

Total Weight |

500kg |

|

Overall Dimensions |

1130×950×2800mm |

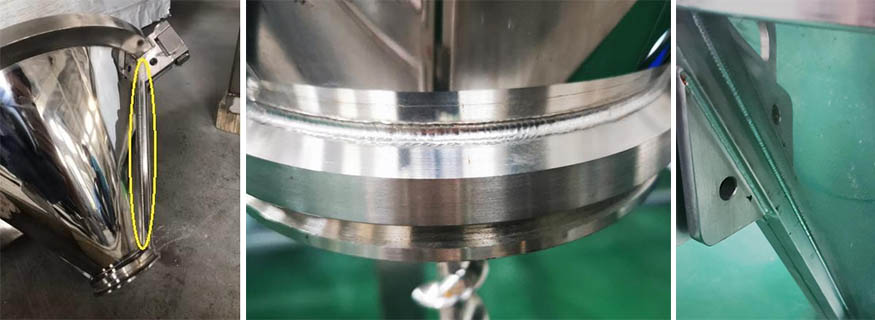

Detailed Parts

Hopper with one-half open

This level split hopper is simple to open and maintain.

Hanging hopper

Because there is no space at the bottom of the

A.Optional Hopper

Type of screw

There are no gaps for powder to hide inside, and it is simple to clean.

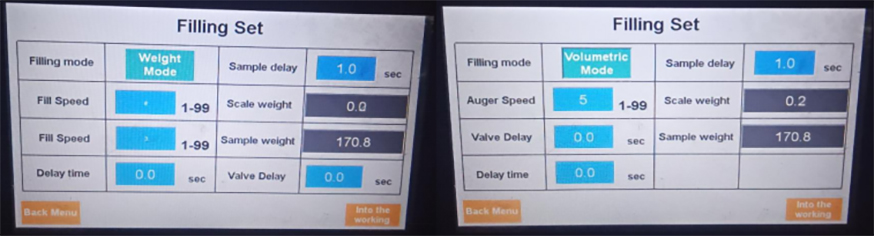

B.Filling Mode

It is appropriate for filling bottles/bags of varying heights. Turn the hand wheel to raise and lower the filler. Our holder is thicker and stronger than others.

Full welding, including the hopper edge, and easy to clean

It is easy to switch between weight and volume modes.

Mode of volume

The powder volume is reduced by turning the screw one round is fixed. The controller will determine how many rotations the screw must make to obtain the desired filling weight.

Mode of weight

Under the filling plate is a load cell that measures the filling weight in real-time. The first filling is quick and mass-filled to achieve 80% of the goal filling weight. The second filling is a bit slow and precise, supplementing the remaining 20% based on timely filling weight.

Weight mode is more accurate, yet a bit slower.

The motor base is made of stainless steel 304.

The entire machine, including the base and motor holder, is built of SS304, which is stronger and of higher quality. The motor holder is not made of SS304.

C. Auger Fixing Way

D.Hand Wheel

E.The Process

F.Motor Base

G.Air Outlet

E. Two output access

Bottles with qualified filling weight pass through a single access point.

Bottles with an unqualified filling weight will be automatically denied access to the opposite belt.

F. Different sizes metering auger and filling nozzles

The filling machine concept states that the amount of powder brought down by turning the auger one circle is fixed. As a result, multiple auger sizes can be applied in different filling weight ranges to achieve more accuracy and save time.

Each size auger has a corresponding size auger tube. As an example, the 38mm screw is suited for filling 100g–250g.