TP-PF Series auger filling machine are the dosing machine which fill right amount of a product into its container (Bottle, jar bags etc). it is suitable for fill powdery or granular materials.

The product is stored in the hopper and dispense the material from the hopper with a rotating screw through the dosing feeder , in each cycle, the screw dispenses a predetermined amount of the product into the package.

Shanghai TOPS GROUP has been focused on powder and particle metering machinery. In the past ten years, we have learned a lot of advanced technologies and applied them to the improvement of our machines.

High filling accuracy

Because the auger filling machine principle is to distribute the material through screw, the accuracy of the screw directly determines the distribution accuracy of the material.

Small size screws are processed by milling machines to ensure that the blades of each screw are completely equidistant. The maximum degree of material distribution accuracy is guaranteed.

In addition, the private server motor controls every operation of the screw, the private server motor. As per the command, servo will move to the position and hold that position. Keeping good filling accuracy than step motor.

Easy to clean

All TP-PF Series machines are made of Stainless steel 304 ,stainless steel 316 material is available according different character material such as Corrosive materials.

Each piece of the machine is connected by full welding and polish, as well as the hopper side gap, it was full welding and no gap exist , very easy to clean.

Before, the hopper was combined by up and down hoppers and inconvenient to dismantle and clean.

we have improved the half-open design of the hopper, no need to disassemble any accessories, only need to open the quick release buckle of the fixed hopper to clean the hopper.

Greatly reduce the time to replace materials and clean the machine.

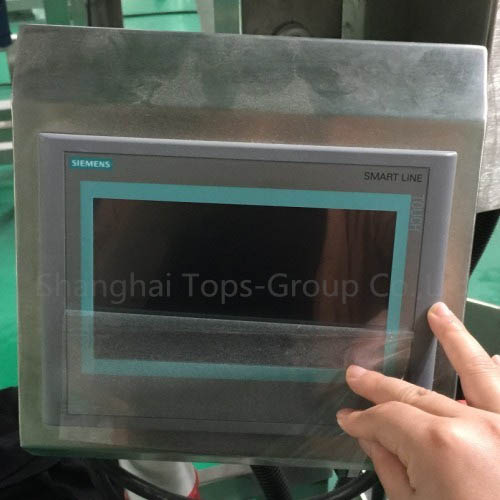

Easy to operate

All TP-PF Series auger type powder filling machine is programmed by PLC and Touch screen, Operator can adjust the filling weight and do parameter setting on touch screen directly.

With Product Receipt Memory

Many factories will replace materials of different types and weights during the production process. Auger type powder filling machine can store 10 different formulas. When you want to change a different product, you only need to find the corresponding formula. There is no need to test multiple times before packaging. Very convenient and convenient.

Multi-language interface

The standard configuration of the touch screen is in English version. If you need configuration in different languages, we can customize the interface in different languages according to your requirements.

Working With different equipment to meet different production needs

Auger filling machine can be assembled with different machines to form a new working mode to meet different production requirements.

It can work with the linear conveyor belt, suitable for automatic filling of different types of bottles or jars.

Auger filling machine can also be assembled with the turntable, which is suitable for packaging a single type of bottle.

At the same time, the it can also work with rotary and Linear type automatic doypack machine to realize automatic packaging of bags.

Electric control part

All electrical appliances brands are well-known international brands, relay contactors are Omron brand relay and contactors, SMC cylinders, Taiwan Delta brand servo motors, which can ensure good working performance.

Regardless of any electrical damage during use, you can buy it locally and replace it.

Machining porcessing

Brand of all bearing is SKF brand, which can ensure the long-term error-free work of the machine.

Machine parts are strictly assembled in accordance with the standards, even in the case of empty machine running without material inside it, the screw will not scrape hopper wall.

Can change to weighing mode

Auger powder filling machine can equip with load cell with high sensitive weighing system. Make sure high filling accuracy.

Different auger size meet different filling weight

In order to make sure filling accuracy, one size screw is suitable for one weight range, Usually :

19mm diameter auger is suitable for filling product 5g-20g.

24mm diameter auger is suitable for filling product 10g-40g.

28mm diameter auger is suitable for filling product 25g-70g.

34mm diameter auger is suitable for filling product 50g-120g.

38mm diameter auger is suitable for filling product 100g-250g.

41mm diameter auger is suitable for filling product 230g-350g.

47mm diameter auger is suitable for filling product 330g-550g.

51mm diameter auger is suitable for filling product 500g-800g.

59mm diameter auger is suitable for filling product 700g-1100g.

64mm diameter auger is suitable for filling product 1000g-1500g.

77mm diameter auger is suitable for filling product 2500g-3500g.

88mm diameter auger is suitable for filling product 3500g-5000g.

The above auger size corresponding to filling weight This screw size is only for conventional materials. If the characteristics of the material are special, we will choose different auger sizes according to the actual material.

Application of auger powder filling machine in different production lines

Ⅰ. Auger filling machine in semi-automatic production line

In this production line , Workers will put the raw materials into the mixer according to the proportions manually. The raw materials will be mixed by the mixer and enter the transition hopper of the feeder. Then they will be loaded and transported into the hopper of semi automatic auger filling machine which can measure and distribute material with certain amount.

Semi automatic auger powder filling machine can control the working of screw feeder, in the auger filling machine’s hopper, there is level sensor, it gives signal to screw feeder when material level is low, then screw feeder will work automatically.

When the hopper is full with material, level sensor gives signal to screw feeder and screw feeder will stop working automatically.

This production line is suitable for both bottle/jar and bag filling, Because it is not a fully automatic working mode, it is suitable for customers with relatively small production capacity.

Specifications of different models of semi automatic auger powder filling machine

|

Model |

TP-PF-A10 |

TP-PF-A11 |

TP-PF-A11S |

TP-PF-A14 |

TP-PF-A14S |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

||

|

Hopper |

11L |

25L |

50L |

||

|

Packing Weight |

1-50g |

1 - 500g |

10 - 5000g |

||

|

Weight dosing |

By auger |

By auger |

By load cell |

By auger |

By load cell |

|

Weight Feedback |

By off-line scale (in picture) |

By off-line scale (in picture) |

Online weight feedback |

By off-line scale (in picture) |

Online weight feedback |

|

Packing Accuracy |

≤ 100g, ≤±2% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

||

|

Filling Speed |

40 – 120 time per min |

40 – 120 times per min |

40 – 120 times per min |

||

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

||

|

Total Power |

0.84 KW |

0.93 KW |

1.4 KW |

||

|

Total Weight |

90kg |

160kg |

260kg |

||

Ⅱ. Auger filling machine in automatic bottle/jar filling production line

In this production line, automatic auger filling machine is equipped with linear conveyor which can realize automatic packaging and filling of bottles/jars.

This type of packaging is suitable for various types of bottle /jar packaging, not suitable for automatic bag packaging.

|

Model |

TP-PF-A10 |

TP-PF-A21 |

TP-PF-A22 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

11L |

25L |

50L |

|

Packing Weight |

1-50g |

1 - 500g |

10 - 5000g |

|

Weight dosing |

By auger |

By auger |

By auger |

|

Packing Accuracy |

≤ 100g, ≤±2% |

≤ 100g, ≤±2%; 100 –500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Filling Speed |

40 – 120 times per min |

40 – 120 times per min |

40 – 120 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

0.84 KW |

1.2 KW |

1.6 KW |

|

Total Weight |

90kg |

160kg |

300kg |

|

Overall Dimensions |

590×560×1070mm |

1500×760×1850mm |

2000×970×2300mm |

Ⅲ. Auger filling machine in Rotary plate automatic bottle/jar filling production line

In this production line, the rotary automatic auger filling machine is equipped with the rotary chuck, which can realize the automatic filling function of the can/jar/bottle. Because the rotary chuck is customized according to the specific bottle size, so this type of packaging machine is generally suitable for single-size bottles/jar/can.

At the same time, the rotating chuck can position the bottle well, so this packaging style is very suitable for bottles with relatively small mouths and achieves a good filling effect.

|

Model |

TP-PF-A31 |

TP-PF-A32 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

25L |

50L |

|

Packing Weight |

1 - 500g |

10 - 5000g |

|

Weight dosing |

By auger |

By auger |

|

Packing Accuracy |

≤ 100g, ≤±2%; 100 –500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Filling Speed |

40 – 120 times per min |

40 – 120 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

1.2 KW |

1.6 KW |

|

Total Weight |

160kg |

300kg |

|

Overall Dimensions |

1500×760×1850mm |

2000×970×2300mm |

Ⅳ. Auger filling machine in automatic bag packaging production line

In this production line ,auger filling machine is equipped with mini-doypack packaging machine .

The mini doypack machine can realize the functions of bag giveing, bag opening, zipper opening, filling and sealing function, and realize automatic bag packaging. because all functions of this packaging machine are realized on one working station, the packaging speed is about 5-10 packages per minute, so it is suitable for factories with small production capacity requirements.

Ⅴ. Auger filling machine in rotary bag packaging production line

In this production line, auger filling machine is equipped with 6/8 position rotary doypack packaging machine.

It can realize the functions of bag giving, bag opening, zipper opening, filling and sealing function, all functions of this packaging machine are realized on different working stations, so the packaging speed is very fast, around 25-40bags/per minute. so it is suitable for factories with large production capacity requirements.

Ⅵ. Auger filling machine in linear type bag packaging production line

In this production line, auger filling machine is equipped with a linear type doypack packaging machine.

It can realize the functions of bag giving, bag opening, zipper opening, filling and sealing function, all functions of this packaging machine are realized on different working stations, so the packaging speed is very fast ,around 10-30bags/per minute, so it is suitable for factories with large production capacity requirements.

Compared with rotary doypack machine, the working principle is almost similar, the difference between this two machines are shape design is different.

FAQ

1. Are you a industrial auger filling machine manufacturer?

Shanghai Tops Group Co., Ltd. was established in 2011, is one of the leading auger filling machine manufacturers in China, have sold our machines to more than 80 countries all over the world.

2. Does your powder auger filling machine have CE certificate?

Yes, All our machines are CE approved , and have auger powder filling machine CE certificate.

3. What products can auger powder filling machine handle?

Auger powder filling machine can fill all kinds of powder or small granule and is widely applied in food, pharmaceuticals, chemical and so on.

Food industry: all kinds of food powder or granule mix like flour, oat flour, protein powder, milk powder, coffee powder, spice, chili powder, pepper powder, coffee bean, rice, grains, salt, sugar, pet food, paprika, microcrystalline cellulose powder, xylitol etc.

Pharmaceuticals industry: all kinds of medical powder or granule mix like aspirin powder, ibuprofen powder, cephalosporin powder, amoxicillin powder, penicillin powder, clindamycin

powder, azithromycin powder, domperidone powder, amantadine powder, acetaminophen powder etc.

Chemical industry: all kinds of skin care and cosmetics powder or industry, like pressed powder, face powder, pigment, eye shadow powder, cheek powder, glitter powder, highlighting powder, baby powder, talcum powder, iron powder, soda ash, calcium carbonate powder, plastic particle, polyethylene etc.

4.How to select an auger filling machine?

Before selecting a suitable auger filler , Please let me know, what state of your production at present ? if you are a new factory, usually a semi-automatic packing machine is suitable for your use.

➢ Your product

➢ Filling weight

➢ Production capacity

➢ Fill into bag or container(bottle or Jar )

➢ Power supply

5. What's the auger filling machine price?

We Have different powder packing machines, based on different product, filling weight, capacity, option, customization. Please contact us to get your suitable auger filling machine solution and offer.