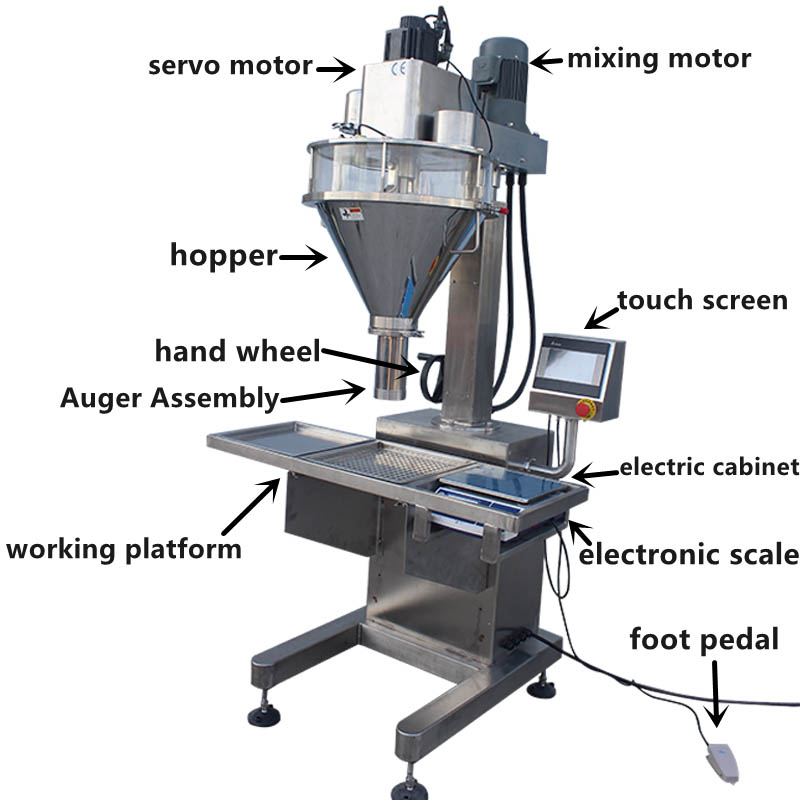

Semi automatic type powder filler

Powder filler breakdown drawing

Consist of

1. Servo motor

2. Mixing motor

3. Hopper

4. Hand-wheel

5. Auger assembly

6. Touch screen

7. Working platform

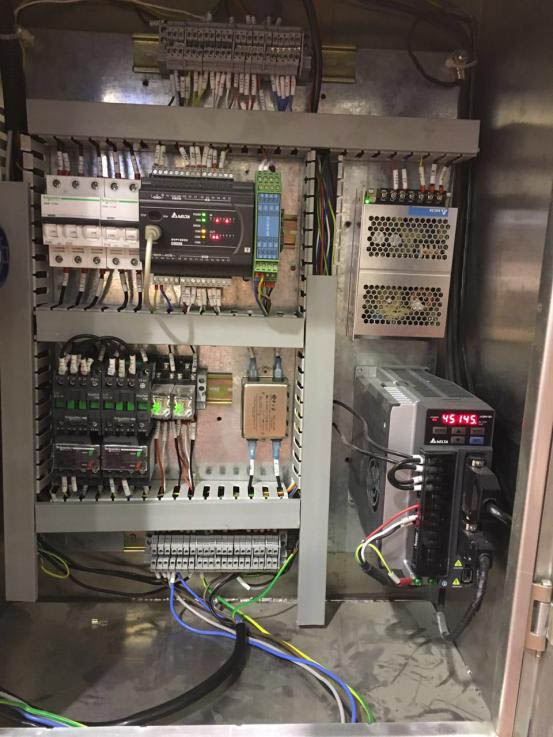

8. Electric cabinet

9. Electronic scale

10. Foot pedal

Operating principle

How does powder filler work?

Servo motor directly drive metering screw, servo motor shaft rotation to control metering screw rotation. The metering screw rotation will take the product flow, product will filled full all screw gap. Metering screw rotate one round, the PLC will convert one round into a fixed pulse, and PLC program controller according to the set weight value, according to the density to calculate the corresponding volume, after the calculation of the corresponding control pulse signal to the servo motor driver, and then the servo driver according to the PLC input signal to drive the servo motor to rotate the corresponding number of turns.

■ Lathing auger screw to guarantee filling accuracy.

■ Delta brand PLC control and touch screen display.

■ Servo motor drives screw to guarantee stable performance.

■ Split type hopper easy open and close without tools, could be washed easily and change auger conveniently to apply different products range of from fine powder to granule and different weight can be packed.

■ Weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials' density change.

■ Save 10 sets of formula on the touch screen.

■ Chinese/English language interface.

■ No-tools removable change parts.

Description

Auger powder filler can do dosing and filling work. It is a volumetric filling machine. Mainly made up of dosing host, electrical distribution box, control cabinet and electronic scale. Because of the meticulously original design, the machine is both suitable for packaging flowable powder and granular illiquid item, including milk powder, monosodium glutamate, solid drink, sugar, dextrose, coffee, fodder, solid medicine, pesticide, granular powder additives, dyes, etc. In addition, due to the use of special auger filler as well as computer real-time tracking, it is of both high speed and high accuracy. It can be used in stand alone applications or can be integrated into automatic conveying lines and bagging machines.

TP series Powder filler machine have a variety of models: single semi-automatic and automatic models, duplex semi-automatic and automatic models, etc., in order to adapt to different production requirements. (For special materials, our company can supply special devices.)

Details

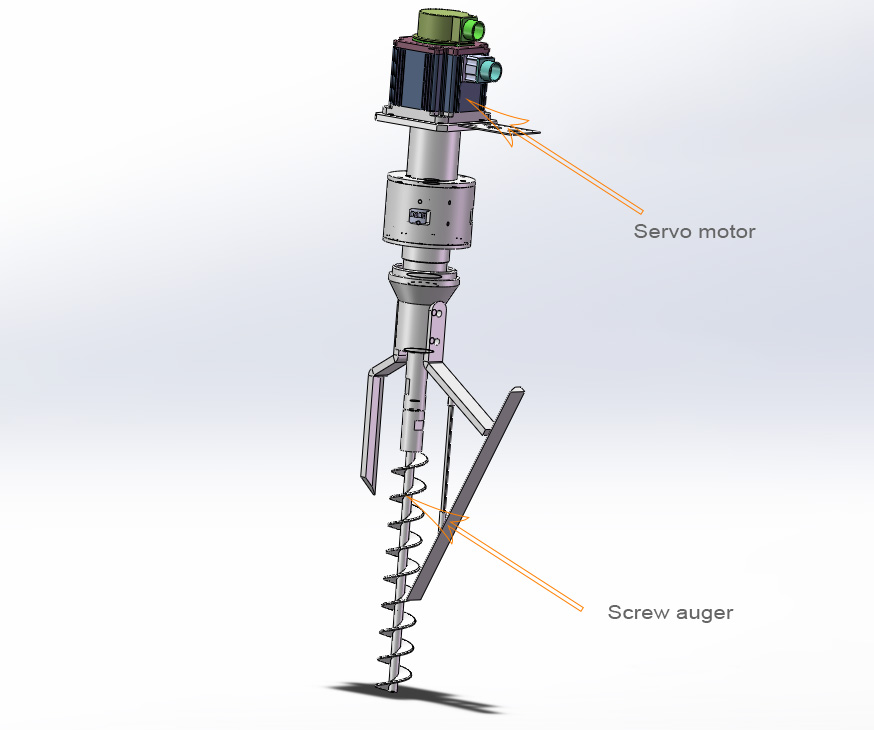

1. Servo motor: servo motor directly drive metering auger, to guarantee the filling accuracy.

2. Mixing motor: mixing motor drive mixing device by chain and sprockets connecting, the mixing device inside of the hopper, to ensure material in the same level of the hopper, so guarantee the filling accuracy.

3. Air outlet: SS material vent outlet, when to load material into the hopper, the air in the hopper need exclude, the vent outlet have a filter to avoid powder dust come out from the hopper.

4. Feeding inlet: the inlet can connect feeding machine discharge, like screw conveyor discharge, vacuum feeder discharge for automatic loading or horn funnel to manual loading.

5. Level sensor: this sensor will sense the material level of the filler hopper, and send signal to let the feeding machine automatically loading.

6. Delta touch screen: set filling weight, speed and other parameters according to your filling requirements.

7. Workbench and overflow collector: convenient to put container on the workbench for filling, and overflow collector can collect spill out material, to ensure the clean working environment.

8. Electric cabinet: use famous brand electrical accessory, to ensure the stability of the machine and the service life of the machine.

9. Screw type metering auger: easy to clean and the most important is no any material hide in the connected section.

10. Hand-wheel: to easy adjust the filling nozzle height, suitable for different height jars/bottles/bags.

11. Split type hopper: To open and close the hopper without tools, could be washed easily and change auger conveniently to apply different products range of from fine powder to granule and different weight can be packed

12. Full welded hopper: without any gap to hide powder dust from air, it’s easy for clean by water or air blowing. And more pretty and stocky.

Main parameter

|

Model |

TP-PF-A10 |

TP-PF-A11/A11N |

TP-PF-A11S/A11NS |

TP-PF-A14/A14N |

TP-PF-A14S/A14NS |

|

Control system |

PLC& touch screen |

PLC & Touch Screen |

PLC & Touch Screen |

||

|

Hopper |

11L |

25L |

50L |

||

|

Packing weight |

1-50g |

1 - 500g |

10 - 5000g |

||

|

Weight dosing |

By auger |

By auger |

By load cell |

By auger |

By load cell |

|

Weight Feedback |

By off-line scale (in picture) |

By off-line scale (in picture) |

Online weight feedback |

By off-line scale (in picture) |

Online weight feedback |

|

Packing accuracy |

≤ 100g, ≤±2% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

||

|

Filling Speed |

40-120 times/ min |

40-120 times/min |

40-120 times/min |

||

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

||

|

Total Power |

0.84 KW |

0.93 KW |

1.4 KW |

||

|

Total Weight |

90kg |

160kg |

260kg |

||

|

Overall Dimensions |

590×560×1070mm |

800×790×1900mm |

1140×970×2200mm |

||

Accessories brand

|

No. |

Name |

Pro. |

Brand |

|

1 |

PLC |

Taiwan |

DELTA |

|

2 |

Touch Screen |

Taiwan |

DELTA |

|

3 |

Servo motor |

Taiwan |

DELTA |

|

4 |

Servo driver |

Taiwan |

DELTA |

|

5 |

Switching powder supply |

|

Schneider |

|

6 |

Emergency switch |

|

Schneider |

|

7 |

Contactor |

|

Schneider |

|

8 |

Relay |

|

omron |

|

9 |

Proximity switch |

Korea |

Autonics |

|

10 |

Level sensor |

Korea |

Autonics |

Automatic type dry powder filler

|

Model |

TP-PF-A20/A20N |

TP-PF-A21/A21N |

TP-PF-A22/A22N |

TP-PF-301/301N |

TP-PF-A302/302N |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

11L |

25L |

50L |

35L |

50L |

|

Packing Weight |

1-50g |

1 - 500g |

10 - 5000g |

1 - 500g |

10 - 5000g |

|

Weight dosing |

By auger |

By auger |

By auger |

By load cell |

By load cell |

|

Packing Accuracy |

≤ 100g, ≤±2% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%

|

≤ 500g, ≤±1%; >500g, ≤±0.5%

|

|

Filling Speed |

40-60 jars per min |

40-60 jars per min |

40-60 jars per min |

20-50 jars per min

|

20-40 jars per min

|

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

0.84 KW |

1.2 KW |

1.6 KW |

1.2kw |

2.3kw |

|

Total Weight |

90kg |

160kg |

300kg |

260kg |

360kg |

|

Overall Dimensions |

590×560×1070mm |

1500×760×1850mm |

2000×970×2300mm |

1500×760×2050mm

|

2000×970×2150mm

|

General Introduction

Automatic type dry powder filler have linear automatic type and rotary automatic type. Automatic type auger powder filler mainly fill bottle/cans/jars, bags can not stand steadily on the conveyor for conveying, so automatic Powder filler machine is not suitable for bags filling. For linear automatic type auger powder filler, it is usually suitable for large opening diameter bottles/cans/jars. As to small opening diameter bottles/cans/jars, rotary type automatic is more suitable, because it can locate more accurately under the filling nozzle for filling.

Dual filling filler with online weighing

This series auger powder filler is a new-designed that we make it on placing the old Turnplate Feeding on one side. Dual auger filling within one line main-assist fillers and the originated Feeding system can keep the high-precision and take off the tiring cleaning of the turntable. Auger powder filler can do the accurate weighing & filling work, and also could combined with other machines to buildup a whole can-packing production line. dry powder filler could be used in filling milk powder, albumen powder, condiment, dextrose, rice flour, cocoa powder, solid drink, and so on.

Main features

■ One line dual fillers, Main & Assist filling to keep work in high-precision.

■ Can-up and horizontal transmitting is controlled by servo and pneumatic system, be more accurate, more speed.

■ Servo motor and servo driver control the screw, keep stable and accurate

■ Stainless steel structure, Split hopper with polishing inner-out make it to cleaned easily.

■ PLC & touch screen make it be easy of operation.

■ Fast-respond weighing system make the strongpoint to real

■ The handwheel make the exchange of different filings to be easily.

■ Dust-collecting cover meet the pipeline and protect environment to pollution.

■ Horizontal straight design make the machine in little area

■ Settled screw setup make no metal pollution in producing

■ Process: can-into → can-up → vibration → filling → vibration → vibration → weighing & tracing → reinforce → weight checking → Can-out

■ With whole system central control system.

Main technical data

|

Dosing mode |

Dual filler filling with online weighing |

|

Filling Weight |

100 - 2000g |

|

Container Size |

Φ60-135mm; H 60-260mm |

|

Filling Accuracy |

100-500g, ≤±1g; ≥500g,≤±2g |

|

Filling Speed |

Above 50 cans/min(#502),Above 60 cans/min(#300 ~ #401) |

|

Power Supply |

3P AC208-415V 50/60Hz |

|

Total Power |

3.4 kw |

|

Total Weight |

450kg |

|

Air Supply |

6kg/cm 0.2cbm/min |

|

Overall Dimension |

2650×1040×2300mm |

|

Hopper Volume |

50L(Main) 25L (Assist) |

Deploy list

| No. | Name | Model Specification | PRODUCING AREA,Brand |

| 1 | Stainless steel | SUS304 | China |

| 2 | PLC | FBs-60MCT2-AC | Taiwan Fatek |

| 3 | HMI | Schneider HMIGXO5502 | Schneider |

| 4 | Filling servo motor | TSB13102B-3NTA | Taiwan TECO |

| 5 | Filling servo driver | TSTEP30C | Taiwan TECO |

| 6 | Filling servo motor | TSB08751C-2NT3 | Taiwan TECO |

| 7 | Filling servo driver | TSTEP20C | Taiwan TECO |

| 8 | Servo motor | TSB08751C-2NT3 | Taiwan TECO |

| 9 | Servo driver | TSTEP20C | Taiwan TECO |

| 10 | Agitator motor | DRS71S4 | SEW/SEW-EURODRIVE |

| 11 | Agitator motor | DR63M4 | SEW/SEW-EURODRIVE |

| 12 | Gear reducer | NRV5010 | STL |

| 13 | Electromagnetic valve | Taiwan SHAKO | |

| 14 | Cylinder | Taiwan Airtac | |

| 15 | Air Filter and booster | AFR-2000 | Taiwan Airtac |

| 16 | motor | 120W 1300rpm Model: 90YS120GY38 | Taiwan JSCC |

| 17 | Reducer | Ratio:1:36,Model:90GK(F)36RC | Taiwan JSCC |

| 18 | Vibrator | CH-338-211 | KLSX |

| 19 | Switch | HZ5BGS | Wenzhou Cansen |

| 20 | Circuit breaker | Schneider | |

| 21 | Emergency switch | Schneider | |

| 22 | EMI Filter | ZYH-EB-10A | Beijing ZYH |

| 23 | Contactor | CJX2 1210 | Wenzhou CHINT |

| 24 | Heat relay | NR2-25 | Wenzhou CHINT |

| 25 | Relay | MY2NJ 24DC | Japan Omron |

| 26 | Switching power supply | Changzhou Chenglian | |

| 27 | AD Weighing Module | DAHEPACK | |

| 28 | Loadcell | Mettler-Toledo | |

| 29 | Fiber sensor | RiKO FR-610 | Korea Autonics |

| 30 | Photo sensor | Korea Autonics | |

| 31 | Level sensor | Korea Autonics |

Accessory list

|

NO. |

NAME |

SPECS |

UNIT |

NUMBER |

REMARK |

|

1 |

SPANNER |

|

PIECE |

2 |

TOOL |

|

2 |

MONKEY SPANNER |

|

PIECE |

2 |

TOOL |

|

3 |

HEXAGON RING SPANNER |

|

SET |

1 |

TOOL |

|

4 |

PHILIPS DRIVER |

|

BUNDLE |

2 |

TOOL |

|

5 |

SCREW DRIVER |

|

BUNDLE |

2 |

TOOL |

|

6 |

PLUG |

|

PIC |

1 |

ACCESSORY |

|

7 |

PRESSURIZING DISC |

|

PIC |

2 |

ACCESSORY |

|

8 |

POISE |

1000G |

PIC |

1 |

ACCESSORY |

|

9 |

HOOPS |

|

PIC |

2 |

ACCESSORY |

|

10 |

DUST-COLLECTING COVER |

|

PIC |

2 |

ACCESSORY |

|

11 |

SCREW |

|

SET |

2 |

ACCESSORY |

|

12 |

USAGE INSTRUCTION |

|

COPY |

1 |

FILE |

Big bag powder filler

This model of dry powder filler is designed mainly for the big bag powder which easily to spout dust and high-accuracy packing requirement. Weight sensor is below the tray, based on the feedback sign given by below weight sensor, to do fast filling and slow filling based on the pre-set weight, to guarantee the high packaging accuracy, dry powder filler do measuring, two-filling, and up-down work, etc. It is specially suitable for filling additives, carbon powder, dry powder of fire extinguisher, and other fine powder which needs high packing accuracy.

TP-PF-B11

TP-PF-B12

Two. characteristics

■ Lathing metering auger screw to guarantee the precise filling accuracy.

■ Delta brand PLC control and touch screen display.

■ Servo motor drives metering auger screw to guarantee stable performance.

■ Split type hopper could be easy open and close without tools, washed easily.

■ Can be setting to semi-auto filling by pedal switch or auto filling.

■ Full stainless steel 304 material.

■ Weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials’ density change.

■ Save 10 sets of formula inside the machine for later use.

■ Replacing the auger parts, different products ranging from fine powder to granule and different weight can be packed.

■ Weight sensor is below the tray, to do fast filling and slow filling based on the pre-set weight, to guarantee the high packaging accuracy.

■ Process: put bag/can(container) on the machine → container raise → fast filling,container declines → weight reaches the pre-set number → slow filling → weight reaches the goal number → take the container away manually.

Three. Technical Parameter

|

Model |

TP-PF-B11 |

TP-PF-B12 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

Quick disconnecting hopper 70L |

Quick disconnecting hopper 100L |

|

Packing Weight |

100g – 10kg |

1kg – 50kg |

|

Dosing mode |

With online weighing; Fast and slow filling |

With online weighing; Fast and slow filling |

|

Packing Accuracy |

100-1000g, ≤±2g; ≥1000g,±0.2% |

1 – 20kg, ≤±0.1-0.2%, >20kg, ≤±0.05-0.1% |

|

Filling Speed |

5 – 20 times per min |

3– 15 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Air supply |

6 kg/cm2 0.05m3/min |

6 kg/cm2 0.05m3/min |

|

Total Power |

2.7KW |

3.2 KW |

|

Total Weight |

350kg |

500kg |

|

Overall Dimensions |

1030×850×2400mm |

1130×950×2800mm |

Optional

Connecting device and dust collector

The gas with powder goes into the dust collector through inlet hose under pressure, air expansion at this time, lower flow velocity will cause the large particles of powder separated from the gas with powder and fells into the dust drawer under the gravity. Other tiny powder is adhered to the filter's outer wall with the air flowing direction and then clean by the vibration device. After purification, the gas goes out from the top outlet through the filter and filter cloth.

Application

Food industry

Chemical industry

Metal cutting industry

Pharmacy industry

Cosmetic industry

Feed industry

Product features

1. Elegant & splendid: Whole machine are made from full stainless steel including draught fan, it is accord with working environment of food grade.

2. High efficiency: The single drum filter of folding micron grade can absorb more powders.

3. Strong strength: Special design of multi blade wind wheel with more stronger suction ability.

4. Convenient cleaning: One-key type vibration cleaning powders, be more efficient to remove the powders which attached the cylinder filter, clean dusts efficiently.

5. Hommization: Adding remote controlling system, be convenient to distance controlling equipment.

6. Lower noises: Special insulation cotton reduce noises more efficiently.

Technical parameter

|

Model |

TP-1.5A |

TP-2.2A |

TP-3.0A |

|

Blowing rate (m³) |

750-1050 |

1350-1650 |

1700-2400 |

|

Pressure (pa) |

940-690 |

|

|

|

Powder (kw) |

1.62 |

2.38 |

3.18 |

|

Equipemnt max noise (dB) |

60 |

70 |

70 |

|

Length |

550 |

650 |

680 |

|

width |

550 |

650 |

680 |

|

height |

1650 |

1850 |

1900 |

|

Filter size (mm) |

325*600*1unit |

380*660*1 unit |

420*700*1 unit |

|

Total weight (kg) |

150 |

250 |

350 |

|

Power upply |

3P 380v 50HZ |

||

Loading system

In order to make the operation of Powder filler machine more convenient. Usually small model powder filler, such as 11L hopper's filler, to equip with a trumpet type entrance to loading; for large hopper's fillers, such as 25L, 50L, 70L 100L hopper's fillers, to equip with screw conveyor or vacuum conveyor for loading, the screw conveyor and vacuum conveyor can automatic to load the filler's hopper, because there is a level sensor inside of the filler's hopper, the hopper product's level is lower, the sensor will send signal to the screw/ vacuum conveyor to running for lading. Once the filler’s hopper product is full, the sensor will give stop running signal to the screw/vacuum conveyor.

Screw conveyor

Consist of

1. Hopper and cover

2. Feeding pipe

3. Feeding motor

4. Vibrating motor

5. Electric cabinet

6. Legs and mobile castor

General introduction

The screw feeder can convey powder and small granule material from one machine to another. It's efficient and convenient. It can work in cooperation with the packing machines to form a production line. So it is widely used in packaging line, especially semi-auto and automatic packaging line. It is mainly used in conveying powder materials, such as the milk powder, protein powder, rice powder, milk tea powder, solid beverage, coffee powder, sugar, glucose powder, food additives, feed, pharmaceutical raw materials, pesticide, dye, flavour, fragrances and so on.

Main features

■ Composed of double motors, feeding motor,and vibrating motor, and each switch control.

■ Hopper is vibratory which make material to be flowing easily, and the size of hopper can customize.

■ Simple structure in linear type ,easy in installation and maintenance.

■ The whole machine except motor is made of SS304 to reach the food grade request.

■ Hopper and feeding pipe connection adopt fast disassemble type, easy installing and disassembling.

■ To cleanup scrapped materials conveniently and design the machine to be: Discharging the material reversely, storing materials at the bottom of hopper pipe, taking out the whole screw.

Specification

|

Main Specification |

HZ-3A2 |

HZ-3A3 |

HZ-3A5 |

HZ-3A7 |

HZ-3A8 |

HZ-3A12 |

|

Charging Capacity |

2m³/h |

3m³/h |

5m³/h |

7m³/h |

8m³/h |

12m³/h |

|

Diameter of pipe |

Φ102 |

Φ114 |

Φ141 |

Φ159 |

Φ168 |

Φ219 |

|

Hopper Volume |

100L |

200L |

200L |

200L |

200L |

200L |

|

Power Supply |

3P AC208-415V 50/60HZ |

|||||

|

Total Power |

610W |

810W |

1560W |

2260W |

3060W |

4060W |

|

Total Weight |

100kg |

130Kg |

170Kg |

200Kg |

220Kg |

270Kg |

|

Overall Dimensions of Hopper |

720×620×800mm |

1023×820×900mm |

||||

|

Charging Height |

Standard 1.85M,1-5M could be designed and manufactured |

|||||

|

Charging angle |

Standard 45 degree ,30-60 degree are also available |

|||||

Production line

Powder filler can works with screw conveyor, storage hopper, auger filler or vertical packing machine,mixing machine or given packing machine, capping machine and labeling machine to form production lines to pack powder or granules product into bags/jars. The whole line will connect by flexible silicone tube and won’t have any dust come out, keep the dust-free working environment.

Production and processing

Factory showroom

Our production workshop have processing master of different kinds of work, welding workers, lathe Turners, assembling workers, polisher, and cleaners, packing workers. Every worker is rigorously trained before he takes up his post. The processing work classification is clear, and every processing link is guaranteed, so the whole mixing machine is guaranteed.

Shanghai Tops Group Co., Ltd. (www. topspacking.com) is professional powder fillers manufacturers for more than ten years in Shanghai. We specialize in the fields of designing, manufacturing, supporting and servicing a complete production line of machinery for different kinds of powder and granular products, our main target of working is to offer the products which are related to the food industry, agriculture industry, chemical industry, and pharmacy field and more. We value our customers and are dedicated to maintaining relationships to ensure continued satisfaction and create win-win relationship.