Video

It consists of capping machine and cap feeder.

1. Cap feeder

2. Cap placing

3. Bottle separator

4. Capping wheels

5. Bottle clamping belt

6. Bottle conveying belt

TP-TGXG-200 Bottle Capping Machine is an automatic capping machine to press and screw lids on bottles. is flexible, durable and works with most containers and caps including flat caps, sport caps, metal lids and many others.

Different to traditional intermittent type capping machine, this machine is a continuous capping type. Compared to intermittent capping, this machine is more efficient, pressing more tightly, and do less harm to the lids. Now it’s widely applied in food, pharmaceutical, chemical industries.

It consists of two parts: capping part and lid feeding part. It works as following: Bottles coming(can joint with auto packing line)→Convey→Separate bottles in same distance→Lift lids→Put on lids→Screw and press lids→Collect bottles.

This model capping machine can cap kinds of different metal & plastic . It is able to integrate to other matched machine in bottling line, fully complete and intelligence control advantage.Also can be equipped with automatic packing line.

■ Solid construction

It is made of 304 stainless steel, built on a heavy duty, tig welded, stainless steel frame construction to provide durability in almost any packaging environment. ,full polish and welding ,easy to clean and maintaince.

■ Advanced HMI operating system, PLC control

You can adjust parameter on touch screen and operate very easily.

The speed of the whole machine can be adjusted.

■ Variable speed control

There are four knobs below touch screen, which maliciously adjust the speed of different functions.

The first knob: Adjust the speed of the bottle conveying belt, that is to say, the running speed of the bottle on the conveyor belt can be adjusted.

The second knob: adjust the speed of the bottle clamper belt to match the speed of the conveyor belt

The third knob: Adjust the speed of the lid conveyor to match the speed of capping.

The fourth knob: Adjust the speed of the bottle separation wheel to match the production speed of the entire line.

■ Fast working performance

Equipped with linear conveyor nad speed of linear conveyor is adjustable , capping speed can reach 100 bpm, freely used separately or combined into production line.

It can be used on the independent rack and is suitable for cap screwing at large scale production lines of customers.

■ High-precision capping rate

6-wheel /3 sets capping in operation makes the screwing speed fast and effectively avoids theft-proofing cap breakage and damage to the bottle caps.

The speed between each set of wheels is fixed according to a certain speed ratio, and the speed of each group of wheels is also different. Which can ensure capping rate >99%

■ Easy to adjust for different cap size

It is possible to cater to varied bottle caps within the scope of this machine without replacement of parts by simply adjusting the synchronous belt, distance between cap screwing wheels and rack height.

Tool -free Adjustable cap chute for different sizes of caps.

■ Suitable for bottles of different shapes

It applies to customers requiring replacement of different specifications of bottles.

Applies to varied tall and short bottles which are round, square, oblate or flat square in shape.

■ F-style Spacer Reversible First Spindle set (on 6 Spindle Capper)

■ Flexible working mode

You can choose the cap feeder to make it fully automatic (ASP). We have the cap elevator, cap vibrator, declined plate and etc. for your choice.

When you use semi-automatic spindle capper, the worker only needs to put the caps onto bottles, during their moving forward, the 3 groups or capping wheels will tighten it.

■ Smart working mode

Lid falling part can remove error lids away(by air blowing and weight measuring).

Rejection system for improperly capped bottles (Optional).

Auto stop and alarm when lack of cap.

Optronic sensor to remove the bottles which are error capped (Option).

Digital display screen to show the size of different bottle, which will be convenient for.

Automatic error lids remover and bottle sensor, assure good capping effect.

■ Work in different production lines

Parameters

|

TP-TGXG-200 Bottle Capping Machine |

|||

|

Capacity |

50-120 bottles/min |

Dimension |

2100*900*1800mm |

|

Bottles diameter |

Φ22-120mm ( customized according to requirement ) |

Bottles height |

60-280mm (customized according to requirement ) |

|

Lid size |

Φ15-120mm |

Net Weight |

350kg |

|

Qualified rate |

≥99% |

Power |

1300W |

|

Matrial |

Stainless steel 304 |

Voltage |

220V/50-60Hz(or customized) |

Standard configuration

|

No. |

Name |

Origin |

Brand |

|

1 |

Invertor |

Taiwan |

Delta |

|

2 |

Touch Screen |

China |

TouchWin |

|

3 |

Optronic Sensor |

Korea |

Autonics |

|

4 |

CPU |

US |

ATMEL |

|

5 |

Interface Chip |

US |

MEX |

|

6 |

Pressing Belt |

Shanghai |

|

|

7 |

Series Motor |

Taiwan |

TALIKE/GPG |

|

8 |

SS 304 Frame |

Shanghai |

BaoSteel |

Shippment & packaging

ACCESSORIES in Box

■ Instruction manual

■ Electrical diagram and connecting diagram

■ Safety operation guide

■ A set of wearing parts

■ Maintenance tools

■ Configuration list (origin, model, specs, price)

Operation procedure

1. Put some bottle on the conveyor.

2. Install the cap arranging (Elevator) and dropping system.

3. Adjust the size of chute based on the specification of cap.

4. Adjust the position of railing and bottle space adjusting wheel according to the diameter of bottle.

5. Adjust the height of bottle fixed belt based on the height of bottle.

6. Adjust the space between two sides of bottle fixed belt in order to fix the bottle tightly.

7. Adjust the height of gum-elastic spin wheel to match the position of cap.

8. Adjust the space between two sides of spin wheel according to the diameter of cap.

9. Press the power switch to start running machine.

Related machines

Automatic Auger Filler

This type semi automatic auger filler can do dosing and filling work. Due to the special professional design, so it is suitable for the fluidity or low-fluidity materials, like coffee powder, wheat flour, condiment, solid drink, veterinary drugs, dextrose, pharmaceuticals, talcum powder, agriculture pesticide, dyestuff, and so on.

Main features

■ Lathing auger screw to guarantee filling accuracy.

■ PLC control and touch screen display.

■ Servo motor drives screw to guarantee stable performance.

■ Split hopper could be washed easily and change auger conveniently to apply different products range of from fine powder to granule and different weight can be packed.

■ Weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials' density change.

■ Save 20 sets of formula inside the machine for later use.

■ Chinese/English language interface.

Specification

|

Model |

TP-PF-A10 |

TP-PF-A21 |

TP-PF-A22 |

|

Control system |

PLC & Touch Screen |

PLC & Touch Screen |

PLC & Touch Screen |

|

Hopper |

11L |

25L |

50L |

|

Packing Weight |

1-50g |

1 - 500g |

10 - 5000g |

|

Weight dosing |

By auger |

By auger |

By auger |

|

Packing Accuracy |

≤ 100g, ≤±2% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

≤ 100g, ≤±2%; 100 – 500g, ≤±1%; ≥500g,≤±0.5% |

|

Filling Speed |

40–120 times per min |

40–120 times per min |

40–120 times per min |

|

Power Supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Total Power |

0.84 KW |

1.2 KW |

1.6 KW |

|

Total Weight |

90kg |

160kg |

300kg |

|

Overall Dimensions |

590×560×1070mm |

1500×760×1850mm |

2000×970×2300mm |

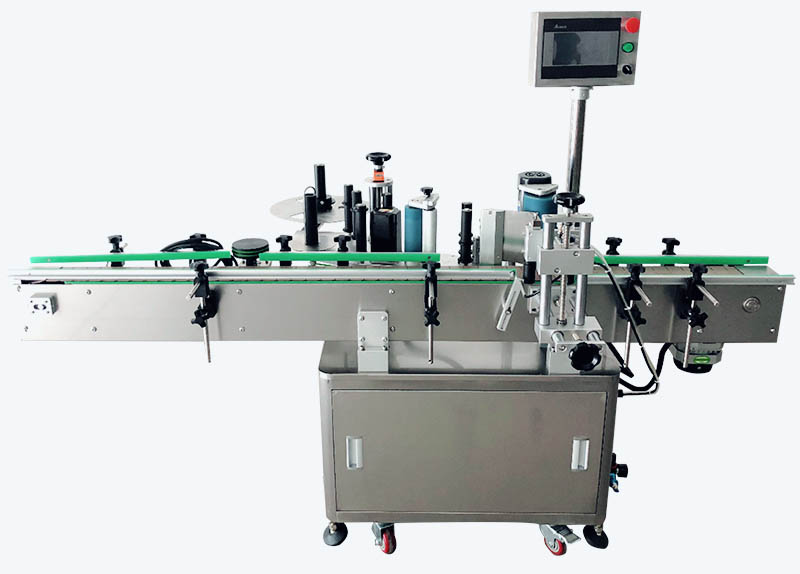

Automatic labeling machine

Descriptive abstract

TP-DLTB-A model labeling machine is economical, independent and easy to operate. It is equipped with automatic teaching and programming touch screen. The built-in microchip stores different job Settings, and the conversion is quick and convenient.

■ Labeling self-adhesive sticker on top, flat or big radians surface of product.

■ Products Applicable: square or flat bottle, bottle cap, electrical components etc.

■ Labels Applicable: adhesive stickers in roll.

Key features

■ Labeling speed up to 200 CPM

■ Touch Screen Control System with Job Memory

■ Simple Straight Forward Operator Controls

■ Full-set protecting device keep operation steady and reliable

■ On-Screen trouble shooting & Help Menu

■ Stainless steel Frame

■ Open Frame design, easy to adjust and change the label

■ Variable Speed with stepless motor

■ Label Count Down (for precise run of set number of labels) to Auto Shut Off

■ Automatic Labeling, work independently or connected to a production line

■ Stamping Coding Device is optional

Specifications

| Working direction | Left → Right (or Right → Left) |

| Bottle diameter | 30~100 mm |

| Label width(max) | 130 mm |

| Label length(max) | 240 mm |

| Labeling Speed | 30-200 bottles/minute |

| Conveyor speed(max) | 25m/min |

| Power source & consumption |

0.3 KW, 220v, 1 Ph, 50-60HZ(Optional) |

| Dimensions |

1600mm×1400mm×860 mm ( L × W × H ) |

| Weight | 250kg |

Automatic Aluminum Foil Sealing Machine Model—TP-HY Series

Consist of

1. Sealing head

2. Automatic conveyor

3. Eliminate optional device

5. Water tank and cooling system

4. Height adjustable hand-wheel

6. Electric cabinet

General Introduction

TP series automatic induction sealer is new generation production which adopts electromagnetic induction technical. The machine is economical and easy to operate. It uses widely in food& beverage, Pharmaceuticals and chemical industry etc. This fully automatic sealing machine can seal the mouth of container with aluminum foil at speeds up to 200 cpm.

Key features

■ Sealing speed up to 120 CPM

■ Heavy duty construction

■ Auto stop and alarm when lack of water

■ Operation stable & less noise

■ Automatic reject caps without aluminum foil

Specifications

| Sealing Speed | 0-250b/m |

| Diameter of bottleneck | 10-150mm (can be customize) |

| Height of bottle | 40-300mm (can be customize) |

| Dimensions | 1600mm×800mm×1160 mm ( L × W × H ) |

| Electrical Requirements | 2000w 220V or 3000w, 380V; 50-60Hz(Optional) |

| Max current | 15A (220V) or 6A (380V) |

| Conveyor speed | 15-20 m/minute |

| Induction frequency | 30-100KHZ |

| Weight | 180kg |

| Working direction | Left → Right (or Right → Left) |

| Main machine dimension | 500x420x1050mm |

| Inductor dimension | 400x120x100mm |

| Conveyor dimension | 1800x1300x800mm (optional) |

Industry Type(s)

■ Cosmetic /personal care

■ Household chemical

■ Food & beverage

■ Nutraceuticals

■ Pharmaceuticals

FAQ

1. Are you a manufacturer of automatic capping machine?

Shanghai Tops Group Co., Ltd. is one of the leading manufacturers of automatic capping machine in China, who has been in packing machine industry for over ten years. We have sold our machines to more than 80 countries all over the world.

We have abilities of designing, manufacturing as well customizing a single machine or whole packing line.

2. What products can automatic capping machine handle?

This in-line spindle capper handles a wide range of containers and offers a quick and easy changeover that maximizes production flexibility. The tightening discs are gentle which will not damage caps but with an excellent capping performance.

3. How to select a Capping machine?

Before selecting a capping machine, Pls advise:

➢ Your bottle material, glass bottle or plastic bottle etc

➢ Bottle shape (it will be better if photo)

➢ Bottle size

➢ Capacity

➢ Power supply

4. What's the price of automatic capping machine?

The price of automatic capping machine based on bottle material, bottle shape, bottle size, capacity, option, customization. Please contact us to get your suitable automatic capping machine solution and offer.

5. What about your company service?

We Tops Group focus on service in order to provide a optimal solution to customers including before-sales service and after-sales service. We have stock machine in showroom for making test to help customer make final decision. And we also have agent in Europe, you can make a testing in our agent site. If you place order from our Europe agent, you also can get after-sale service in your local. We always care about your capping machine running and after-sales service is always at your side to ensure everything runs perfectly with guaranteed quality and performance.

Regarding after-sales service, if you place order from Shanghai Tops Group, within one year’s warranty, if the capping machine have any problem, we will free send the parts for replacement, including express fee. After warranty, if you need any spare parts, we will give you the parts with cost price. In case of your capping machine fault happening, we will help you to deal with it in first time, to send picture/video for guidance, or live online video with our engineer for instruction.

6. Do you have the ability of design and propose solution?

Of course, we have professional design team and experienced engineer. For example, if your bottle/jar diameter range is large, we will design adjustable width conveyor to equip with the capping machine.

7. What shape bottle/jar can capping machine handle?

A: It is best suitable for Round and square, other irregular shapes of Glass, Plastic, PET, LDPE, HDPE Bottles, need confirm with our engineer. The bottles/jars hardness must can be clamped, or it can not screw tight.

Food industry: all kinds of food, spices bottle/jars, drink bottles.

Pharmaceuticals industry: all kinds of medical and health care products bottles/jars.

Chemical industry: all kinds of skin care and cosmetics bottles/jars.

8. Delivery time

Machines &molds order usually takes 30 days after pre-payment received. Preforms orders depends on the qty. Please inquiry sales.

9. What is the package?

Machines will be packed by standard sea-worthy wooden case.

10. Payment term

We can accept T/T. Alibaba Trade assurance order, Western Union, Paypal. Generally 30% deposits and 70% T/T before shipping.

1. Sign the Contact or Proforma invoice.

2. Arrange 30% deposit to our factory.

3. Factory arrange production.

4. Testing & detecting the machine before shipping.

5. Inspected by customer or third agency through online or site test.

6. Arrange the balance payment before shipment.