We the Tops Group Co., LTD. is a professional packaging machine supplier that specialize in the fields of designing, manufacturing, supporting, and servicing a complete line of machinery for different types of liquid, powder, and granular products. We utilized in the production of agriculture industry, chemical industry, food industry, and pharmacy fields, and many more. We are commonly known for its advanced design concept, professional technique support and high quality machines.

Tops-Group looks forward to provide you with amazing service and exceptional products of machines. All together let’s create long term valued relationship and build a successful future.

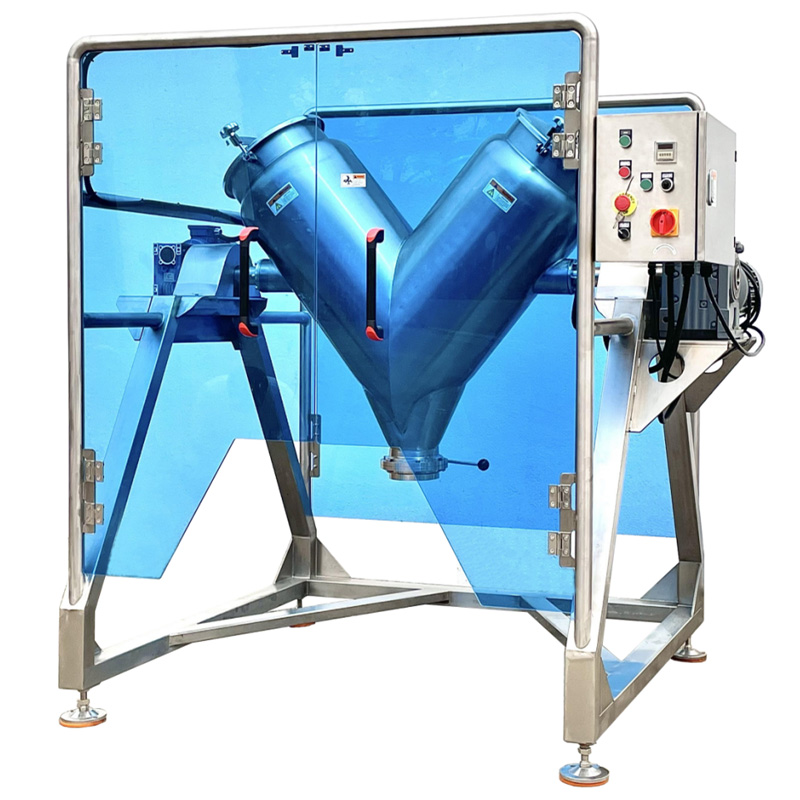

V Mixer

Did you know that v mixer can mix intimate dry free flowing solid materials?

Well, the "V" Mixer is a versatile and effective mixing machine for homogeneously combining dry materials. V Mixer is suitable it's best for powder, granules-type materials and etc. It consists of a work-chamber connected by two cylinders forming a “V " shape. It has two opening on top of the "V" shape tank that enables the v mixer to be conveniently discharged the materials at the end of the mixing process. The v mixer can be equipped with an automated loading system for introducing powders and granules. It is commonly used in Pharmaceutical, Food, Chemical, Cosmetic and etc.

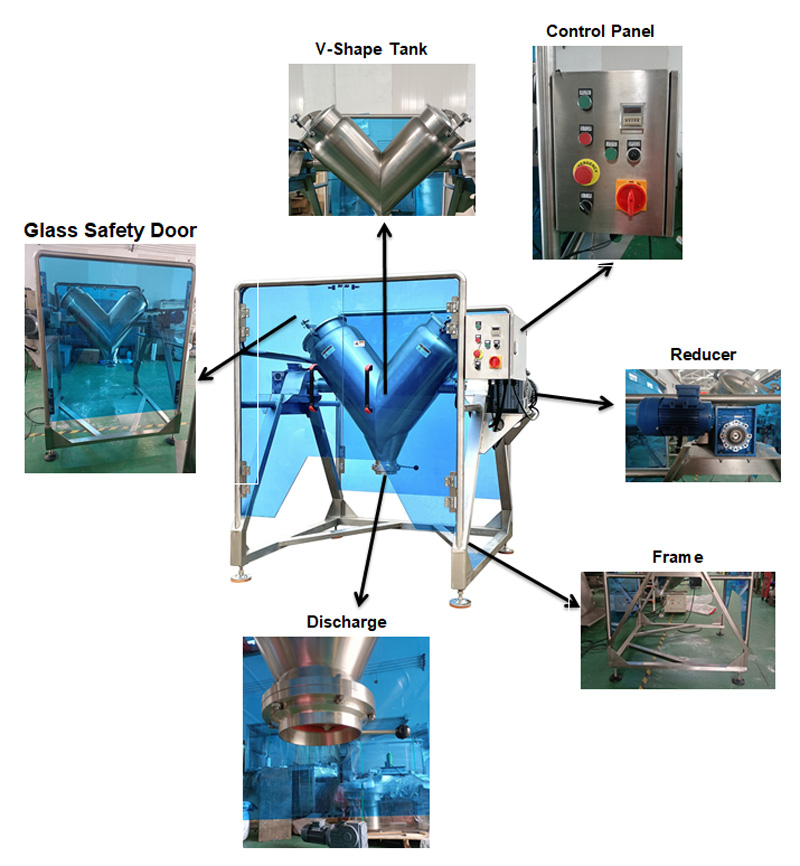

V Mixer Composition

This V Mixer is composed of different external parts.

V Mixer Materials

All materials of V Mixer are stainless steel 304

Internal finish parts are fully welded and bright polish

External finish parts are fully welded and bright polish

V Mixer Working Principles

V mixer is composed of mixing tank, frame, plexiglass door, control panel system and other components. It is made up of two cylinders that are positioned in a "V" shape. An intensifier bar can be added to the V mixer which can help in mixing and breaking up materials. The amount of material put into the v mixer has an impact on its efficiency. The v mixer recommended blender's fill-up volume is 40 to 60% of the overall mixing volume. For this the materials inside the machine can move freely and result to a good mixture. For instance, if the amount of material in the v mixer is increased to 50% from the total volume, it requires to works by batch in filling material inside the tank and the time required for homogeneous mixing might be doubled. With uniformity of more than 99%, this means that the product in the two cylinders moves into the central common area with each turn of the v mixer, and this process, is done continually.

V Mixer Features

● V Mixer’s internal and external surface of the mixing tank is fully welded and polished.

● The v mixer consists of 2 models with a total capacity of 100 to 200 liters and a useful capacity of 50% of the total.

● All material is made of stainless steel 304. Stainless steel 316 is optional

● V mixer machine has plexiglass safe door with a safety button.

● The "V" shape design allows the materials to move around freely, resulting in good mixture.

● Ensure to have safe operation

● Charging and discharging of material is easy.

● V Mixer is easy and safe to clean

V Mixer Loading and Discharging

As the entire shell is rotating, the v mixer should be separated from the remainder of the cycle during mixing. Loading and discharging can be easily done by the operator and this can produce dust outflows. To stay away from this, the v mixer can be situated to tipping station and release container because of flexibility, yet requiring some operator’s mediation.

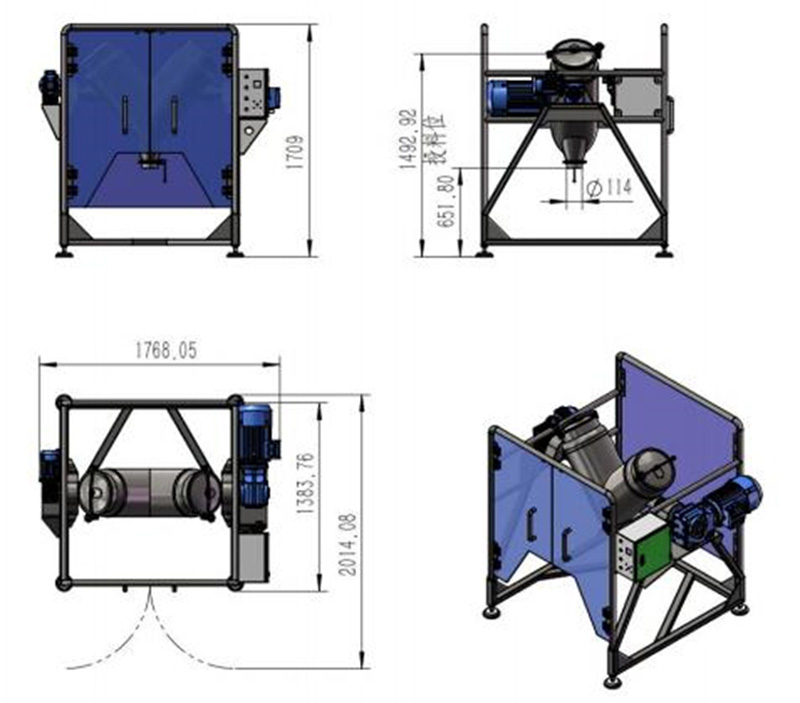

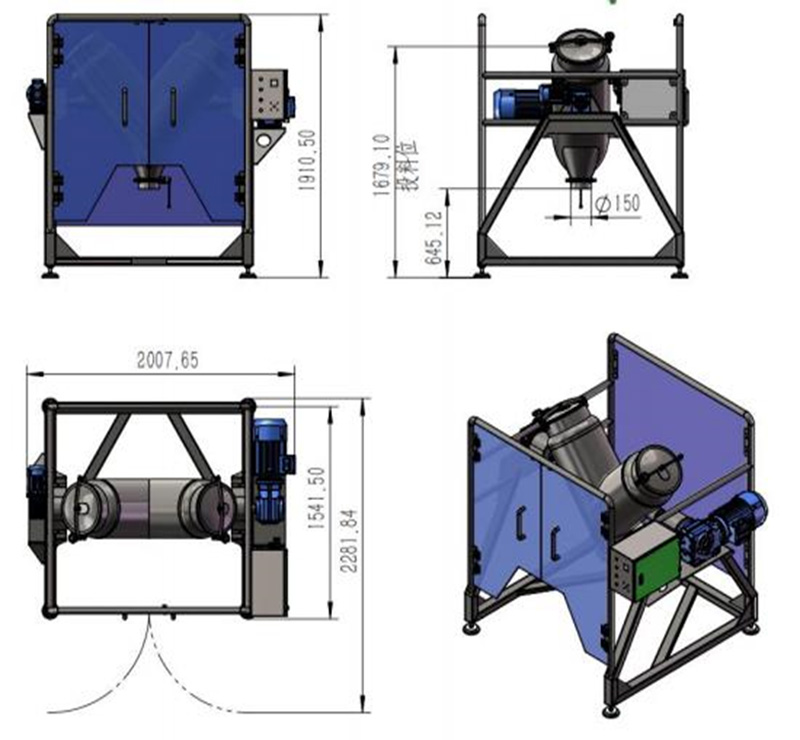

V Mixer Technical Parameters

| Item | TP-V100 | TP-V200 |

| Total Volume | 100L | 200L |

|

Effective Loading Rate |

40%-60% | 40%-60% |

| Power | 1.5kw | 2.2kw |

| Stirrer Motor Power | 0.55kw | 0.75kw |

| Tank Rotate Speed | 0-16 r/min | 0-16 r/min |

| Stirrer Rotate Speed | 50r/min | 50r/min |

| Mixing Time | 8-15mins | 8-15mins |

| Charging Height |

1492mm |

1679mm |

| Discharging Height |

651mm |

645mm |

| Cylinder Diameter |

350mm |

426mm |

| Inlet Diameter |

300mm |

350mm |

| Outlet Diameter |

114mm |

150mm |

| Dimension |

1768x1383x1709mm |

2007x1541x1910mm |

| Weight |

150kg |

200kg |

Standard Configuration of V Mixer

| No. | Item | TP-V100 | TP-V200 |

| 1 | Motor | Zik | Zik |

| 2 | Stirrer Motor | Zik | Zik |

| 3 | Inverter | QMA | QMA |

| 4 | Bearing | NSK | NSK |

| 5 | Discharge Valve | Butterfly Valve | Butterfly Valve |

V Mixer Unique Design

V Mixer is a newly design mixing machine that is made of stainless steel. V mixer has a unique design and the base is made up of stainless steel square tube. The frame is made up of stainless steel round tube and easy safe to clean.

Plexiglass Safe Door

V Mixer has plexiglass safe door, it is made for operator’s safety. It has safety button and when the door is open the machine also automatically stop.

Formed of V-Shape

V Mixer consists of two inclined cylinders that connects together in a form of V-shape and made up of stainless steel. V mixer tank is fully welded and mirror polished, no material storage and easy to clean.

Charging Port

V Mixer Removable Cover

V mixer feeding inlet has removable cover which is made of stainless steel and rubber sealing edible silicone strip. It is easy to operate through pressing the lever and it gives good performance.

Inside of the Tank Example

Example of charging or feeding powder material to the v mixer, we can ensure the convenience and satisfaction with using v mixer. Inside of v mixer tank is fully welding and polished. It is easy and safe to clean, no dead angle in discharging.

V Mixer Charging and Discharging Button

V mixer has also inching button for the tank to turn at appropriate charging (or discharging) position for feeding and discharging materials.

You can set the time according to the material and mixing process.

V Mixer Safety Switch

V mixer has also safety switch for the safety of the operator, to avoid personnel injury.

Optional Function of V Mixer

V Mixer Stainless Steel Material

V Mixer material is made of stainless steel 304 and can also be made of 316 and 316 L stainless steel and it can surely meet the good grade standard.

V Mixer Intensifier Bar

Inside of V mixer tank has removable (optional) intensifier bar it helps to increases the mixing efficiency. It is fully welding and mirror polished. It is easy and safe to clean, no dead angle

Speed Adjustment

V mixer can also customize speed adjustable, by installing a frequency converter; the v mixer can be adjusted to the speed

Capacity Volume

100 Volume-V Mixer

200 Volume-V Mixer

Shipment

Packaging

Factory Show

Service & Qualifications

■ Warranty: TWO YEAR warranty

ENGINE THREE YEARS warranty

Life-long service

(Warranty service will be honored if the damage is not caused by human or improper operation)

■ Provide accessory parts in favorable price

■ Update configuration and program regularly

■ Respond to any question in 24 hours

■ Payment Term: L/C, D/A, D/P, T/T, Western Union, Money Gram, PayPal

■ Price Term: EXW, FOB, CIF, DDU

■ Package: cellophane cover with wooden case.

■ Delivery Time: 7-10 days (standard model)

30-45days (customized machine)

■ Note: V Blender shipped by air is about 7-10 days and 10-60 days by sea, it depends on a distance.

■Place of Origin: Shanghai China

If you have questions and inquiries feel free to contact us.

Tel: +86-21-34662727 Fax: +86-21-34630350

E-mail: wendy@tops-group.com

Address: N0.28 Huigong Road, Zhangyan Town, Jinshan District,

Shanghai China, 201514

THANK YOU AND WE LOOK FORWARD

TO ANSWER YOUR INQUIRY!