APPLICATION

This v-shaped mixer machine is commonly used in dry solid blending materials and used in the following application:

• Pharmaceuticals: mixing prior to powders and granules.

• Chemicals: metallic powder mixtures, pesticides and herbicides and many more.

• Food processing: cereals, coffee mixes, dairy powders, milk powder and many more.

• Construction: steel preblends and etc.

• Plastics : mixing of master batches, mixing of pellets, plastic powders and many more.

Working Principle

This v-shaped mixer machine is composed of mixing tank, frame, transmission system, electrical system etc. It relies on two symmetric cylinders to gravitative mix, which makes materials constantly gather and scattered. It takes 5 ~ 15 minutes to mix two or more powder and granular materials evenly. The recommended blender's fill-up volume is 40 to 60% of the overall mixing volume. The mixing uniformity is more than 99% which means that the product in the two cylinders moves into the central common area with each turn of the v mixer, and this process, is done continually.The inner and outer surface of the mixing tank is fully welded and polished with precision processing, which is smooth, flat, no dead angle and easy to clean.

PARAMETERS

| Item | TP-V100 | TP-V200 | TP-V300 |

| Total Volume | 100L | 200L | 300L |

| Effective Loading Rate | 40%-60% | 40%-60% | 40%-60% |

| Power | 1.5kw | 2.2kw | 3kw |

| Tank Rotate Speed | 0-16 r/min | 0-16 r/min | 0-16 r/min |

| Stirrer Rotate Speed | 50r/min | 50r/min | 50r/min |

| Mixing Time | 8-15mins | 8-15mins | 8-15mins |

| Charging Height | 1492mm | 1679mm | 1860mm |

| Discharging Height | 651mm | 645mm | 645mm |

| Cylinder Diameter | 350mm | 426mm | 500mm |

| Inlet Diameter | 300mm | 350mm | 400mm |

| Outlet Diameter | 114mm | 150mm | 180mm |

| Dimension | 1768x1383x1709mm | 2007x1541x1910mm | 2250* 1700*2200mm |

| Weight | 150kg | 200kg | 250kg |

STANDARD CONFIGURATION

| No. | Item | Brand |

| 1 | Motor | Zik |

| 2 | Stirrer Motor | Zik |

| 3 | Inverter | QMA |

| 4 | Bearing | NSK |

| 5 | Discharge Valve | Butterfly Valve |

DETAILS

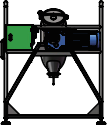

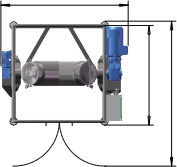

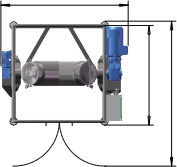

STRUCTURE & DRAWING

TP-V100 Mixer

Design Parameters of V Mixer Model 100:

1. Total Volume: 100L;

2. Design Rotating Speed: 16r/min;

3. Rated Main Motor Power: 1.5kw;

4. Stirring Motor Power: 0.55kw;

5. Design Loading Rate: 30%-50%;

6. Theoretical Mixing Time: 8-15min.

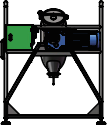

TP-V200 Mixer

Design Parameters of V Mixer Model 200:

1. Total Volume: 200L;

2. Design Rotating Speed: 16r/min;

3. Rated Main Motor Power: 2.2kw;

4. Stirring Motor Power: 0.75kw;

5. Design Loading Rate: 30%-50%;

6. Theoretical Mixing Time: 8-15min.

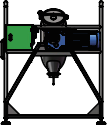

TP-V2000 Mixer

Design Parameters of V Mixer Model 2000:

1. Total Volume: 2000L;

2. Design Rotating Speed: 10r/ min;

3. Capacity :1200L;

4. Max Mixing Weight: 1000kg;

5. Power: 15kw

CERTIFICATES