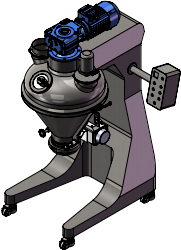

APPLICATION

Vertical ribbon blender for dry powder mixing

Vertical ribbon blender for powder with liquid spray

Vertical ribbon blender for granule mixing

MAIN FEATURES

• There are no dead angles at the bottom, ensuring a uniform mixture without any dead angles.

• The small gap between the stirring device and the copper wall effectively prevents material adhesion.

• The highly sealed design ensures a uniform spray effect, and the products adhere to GMP standards.

• Utilizing internal stress relief technology results in stable system operation and reduced maintenance costs.

• Equipped with automatic operation timing, overload protection, feeding limit alarms, and other functions.

• Incorporated interrupted wire rod anti-sport design enhances mixing uniformity and reduces mixing time.

SPECIFICATION

| Model | TP-VM-100 | TP-VM-500 | TP-VM-1000 | TP-VM-2000 |

| Full Volume (L) | 100 | 500 | 1000 | 2000 |

| Working Volume (L) | 70 | 400 | 700 | 1400 |

| Loading Rate | 40-70% | 40-70% | 40-70% | 40-70% |

| Length(mm) | 952 | 1267 | 1860 | 2263 |

| Width(mm) | 1036 | 1000 | 1409 | 1689 |

| Height(mm) | 1740 | 1790 | 2724 | 3091 |

| Weight(kg) | 250 | 1000 | 1500 | 3000 |

| Total Power (KW) | 3 | 4 | 11.75 | 23.1 |

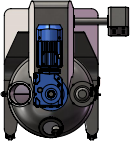

DETAILED PHOTOS

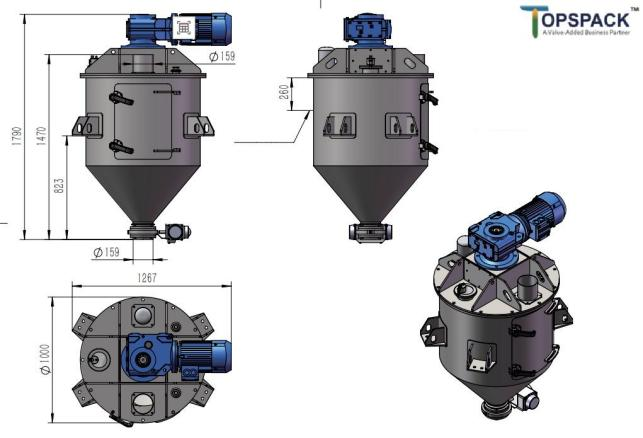

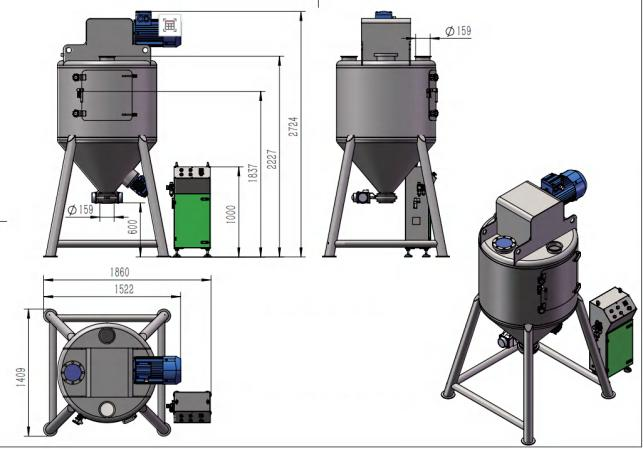

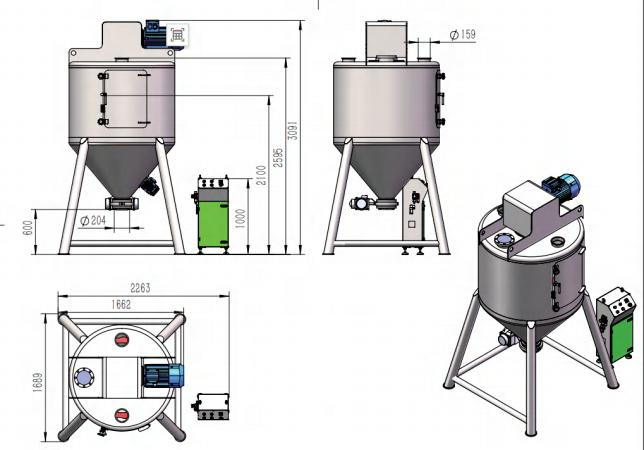

DRAWING

Design parameters for a 500L vertical ribbon mixer:

1. Designed total capacity: 500L

2. Designed power: 4kw

3. Theoretical effective volume: 400L

4. Theoretical rotational speed: 0-20r/min

Design parameters for a 1000L vertical mixer:

1. Theoretical total power: 11.75kw

2. Total capacity: 1000L Effective volume: 700L

3. Designed maximum speed: 60r/min

4. Suitable air supply pressure: 0.6-0.8MPa

Design parameters for a 2000L vertical mixer:

1. Theoretical total power: 23.1kw

2. Total capacity: 2000L

Effective volume: 1400L

3. Designed maximum speed: 60r/min

4. Suitable air supply pressure: 0.6-0.8MPa

TP-V200 Mixer

Design parameters for a 100L vertical ribbon mixer:

1. Total capacity:100L

2. Theoretical effective volume: 70L

3. Main motor power: 3kw

4. Designed speed: 0-144rpm (adjustable)

CERTIFICATES